Industrial edge

Secure, local, high performance OT edge processing

What are the drivers for Industry 4.0 transformation?

Industry 4.0 hinges on transforming asset intensive industries by digitalizing processes and systems across the industry value chains and enabling them to become more efficient, agile and sustainable, providing a better and safer environment for workers.

Why do industries need an on-premises edge?

High performance processing

Explosion of data

In current brownfield environments a large majority of industrial assets and workers are not yet connected and widespread deployment of additional Industrial IoT (IIoT) is expected. The volume and growth of raw historical and real-time operational data stored and generated in your plants will require high-capacity data processing so you can extract greater insight for better decision making and increased automation.

Low latency

OT system availability

Total control over data

Explosion of data

In current brownfield environments a large majority of industrial assets and workers are not yet connected and widespread deployment of additional Industrial IoT (IIoT) is expected. The volume and growth of raw historical and real-time operational data stored and generated in your plants will require high-capacity data processing so you can extract greater insight for better decision making and increased automation.

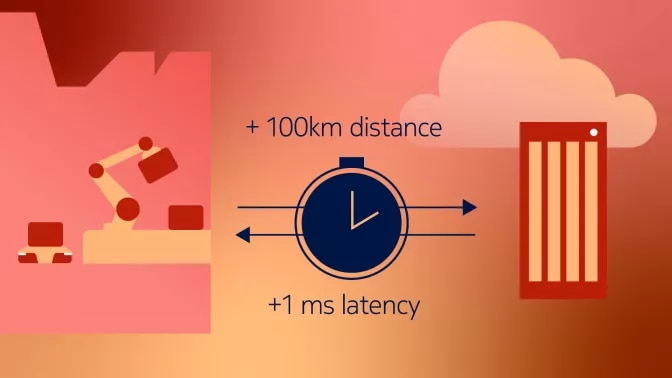

On-prem edge processing enables the lowest latency

The physical distance between devices on the production floor and the processing server is crucial for real-time processing. When you rely on data being processed in the cloud, several 100kms from your site, this adds significant latency and diminishes network service reliability – not an option for your mission critical operations.

With on prem edge processing OT processes can continue to operate when internet is down

To ensure business continuity and uninterrupted mission-critical operations for worker safety or real-time machine control use cases, industries need edge processing solutions with very high availability (>99.99%), high resiliency and in certain deployment scenarios physical, geo-redundant architectures for fast disaster recovery.

On-prem edge processing reduces risks of exposure and compromised data

One key enterprise requirement is to have total control over all sensitive OT data, which is often a challenge if data processing and analytics is done at a remote compute location. The latest fast IT/OT convergence trend – eliminating the airgap between IT and OT - generates potential security vulnerabilities that also need to be handled.

What is the difference between IT and OT?

Information Technology (IT)

Traditional information technology (IT) systems that handle generic data, communication functions and horizontal applications (e.g., email, editing office documents, access to shared data in the cloud) can easily tolerate latency and normal IT service levels and usually operate well on standard local data center solutions, or in hybrid or fully cloudified architectures.

Operational Technology (OT)

OT used for connecting, monitoring, managing, and securing industrial operations, such as robots, industrial control systems, supervisory control and data acquisition (SCADA) systems, programmable logic controllers (PLCs) and computer numerical control solutions, requires low latency and extremely high availability.

How is the OT edge different from IT solutions?

Manufacturing, mining, oil and gas, utilities and transportation use cases require high reliability, high availability and stable low latency to maintain continuous operations and allow rapid response to issues. These needs cannot be met by the service levels offered by locally deployed or cloudified IT solutions. In the case of remote cloud-based processing, service availability and reliability depend on the service quality of the internet link.

Data security

With the acceleration of IIoT many industrial processes can be monitored and controlled remotely. Isolation of the OT systems from your enterprise IT systems as a security policy is therefore more challenging as all systems are interconnected. An on-premises edge can offer a solution for the increased security needs of IT/OT convergence by providing the necessary protection for assets and applications in the OT environment. Further enhanced security measures, such as zero trust security or enhanced, OT-specific firewall solutions – should be available to the on-prem edge as separately deployable applications.

Resiliency

A locally deployed ruggedized edge meets OT resiliency (as well as availability and reliability) requirements and plays an important role if you want to remove external dependencies. This means carrier-grade (>99.99%) availability that can be further improved by implementing geo-redundancy and automated failover mechanisms.

Data sovereignity

As all OT data is sensitive, local processing using an on-premises edge provides necessary data sovereignty and confidentiality ensuring data never leaves your enterprise campus.

How can you extract more value from your data?

Ecosystem neutrality

Our edge is ecosystem neutral, allowing you to tap into the capabilities of an array of innovative applications for digitalization. This is a key competitive advantage, ensuring maximum flexibility to on-board your own, your preferred vendors or legacy applications running in your site today.

Diverse range of applications

Easy application deployment

Our edge is ecosystem neutral, allowing you to tap into the capabilities of an array of innovative applications for digitalization. This is a key competitive advantage, ensuring maximum flexibility to on-board your own, your preferred vendors or legacy applications running in your site today.

To propel you along your industry digitalization journey, an on-premises edge solution must also be able to connect all your industrial assets and be native in translating communication protocols between north and southbound directions.

It must run advanced data analytics, support asset tracking and help connected workers complete their tasks using digital immersive tools instead of pen and paper. These capabilities should be enabled through deployable applications from a wide variety of industrial partners.

Access to applications should be enabled with “click-to-deploy” simplicity from a trusted source (such as an industrial application catalog) offering a wide array of validated, pre-tested third party vendor applications.

By adopting one platform for industry digitalization incorporating reliable, secure connectivity, powerful edge processing, ruggedized devices to connect people and machines and a range of vendor applications, you can solve the challenges of Industry 4.0 transformation. Further, by adopting such a solution ‘as-a-Service’ you can evolve at your own pace and achieve business goals in the most intuitive way.

Resources

Get in touch with a Nokia expert

Please complete the form below.

The form is loading, please wait...