Nokia Visual Position and Object Detection

Nokia Visual Position and Object Detection enables industries with real-time, tagless tracking and positioning.

Fixed camera-based tracking for a high-level view of your industrial site

Every industry can benefit from tracking and positioning solutions. It’s crucial to understand how workers navigate a campus, how automated machines execute tasks and which paths they follow, how the ecosystem operates, how hazards and emergencies can be avoided, or in case of such an event, how to react and locate those in need rapidly.

Nokia Visual Position and Object Detection provides industries with a tracking and positioning solution that is tag-less and that can leverage existing camera systems. It can be trained to detect anything on site without being intrusive.

- Tagless tracking of people and objects

- Can track anything it is trained to

- Provides low latency capabilities used with MX Grid

- Works with existing camera systems, connected to MX Grid

- Flexible system that can be combined with other positioning apps

How will Nokia Visual Position and Object Detection benefit your business?

Improved visibility of industrial site activities

Understanding the movements of machines and people can provide greater awareness around operational processes, potential bottlenecks and issues.

High asset availability and utilization

Tracking an item’s location can cut the time spent searching for it and improve asset utilization.

Increased worker safety

By identifying the locations of vehicles and workers potential collisions can be avoided. In an emergency, automated alerts ensure quick response so people and assets can be reached more rapidly.

How does Nokia Visual Position and Object Detection work?

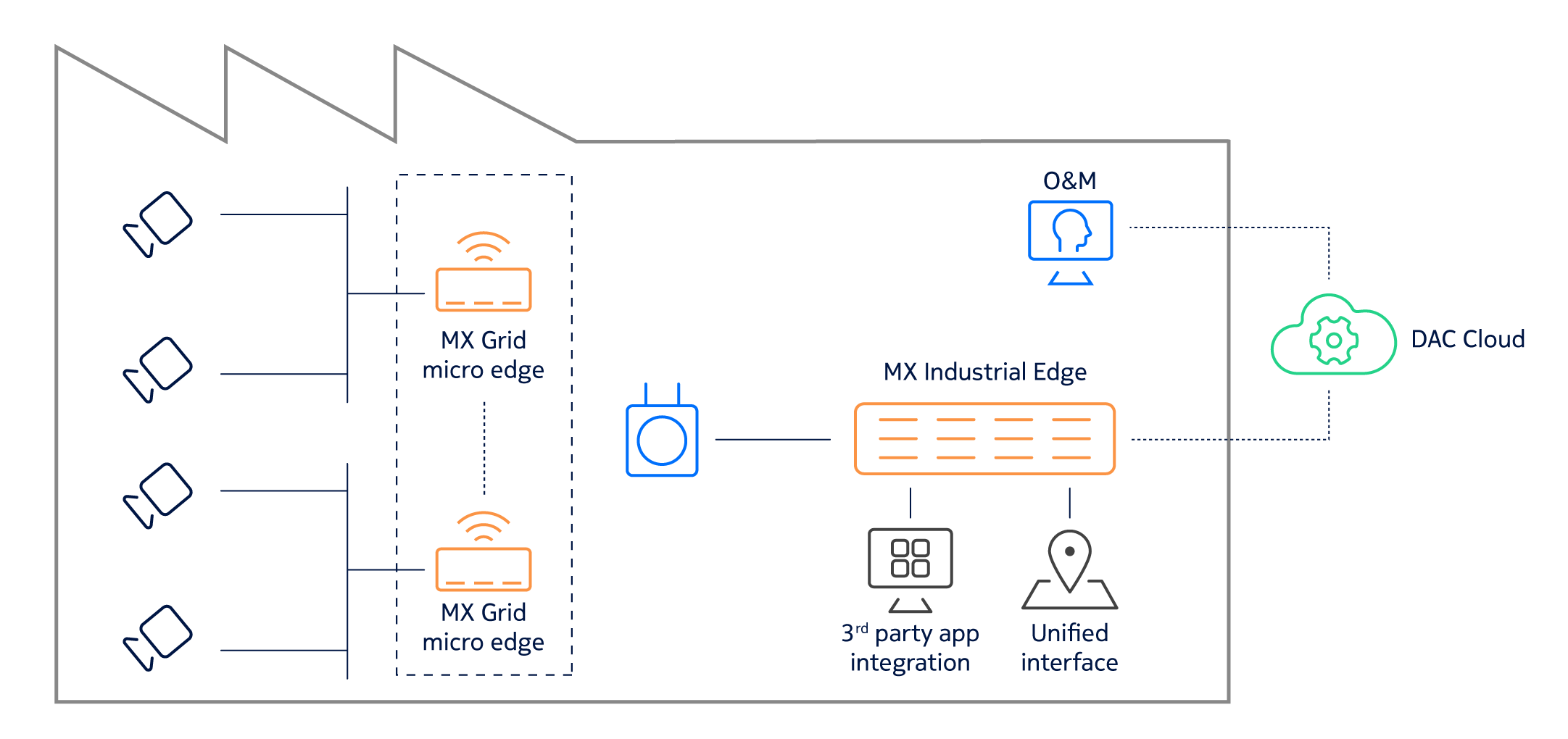

Visual Position and Object Detection relies on the hyperconnected micro edge MX Grid, which hosts the latency-sensitive and compute-intense applications. Video feeds are pre-processed, and only relevant data is shared with the app running on Nokia MX Industrial Edge to update the real time environment model.

Related solutions

Worker Safety Solution

Worker safety is one of the main drivers of digitalization and workplace automation, but as it adds complexity, increases maintenance tasks and requires manual effort, the penetration is slow. Worker safety applications heavily rely on information regarding where people and machines are located at any given time. Tracking and positioning solutions offer a foundation for worker safety applications, however most rely on tracking units and trackers, which involves continuous planning, deployment and maintenance costs.

Now you can benefit from a solution that uses video-based tracking and does not require tags and can leverage existing camera systems. Our Worker Safety Solution can detect anything on site that it has been trained to without being intrusive. It uses the information provided by VPOD, applies the specified rules to defined situations and acts accordingly.

Typical dangerous scenarios include:

-

Detection of machine proximity to unaware workers - The camera network detects when a transport vehicle, (ie.forklift) is dangerously close to workers, who may not be aware that it’s close by. Wall mounted lights and loudspeakers can be activated to warn workers of the approaching danger or send an alert to their handheld devices. Alarms can also be raised to the plant manager in the control room for further action.

-

Geofenced zones - can be dynamically created and adjusted to temporarily restrict workers from entering an area with ongoing activity or high-speed traffic or even completely sealing off areas where machines operate. This can significantly reduce the risk of accidents and raise employee awareness and safety, by alerting them of potential dangers. Likewise, if someone enters a geofenced area, an alert can be raised to the workers and plant manager to take action needed for injury avoidance or possible asset damage.

-

Personal protective equipment (PPE) non-compliance - is one of the main causes of severe injuries. By implementing our camera-based solution, PPE compliance can be tracked and controlled to avoid potential injuries originating from not wearing the right gear.

- Accident response - There are instances when injuries simply cannot be prevented. In these cases, a quick response can have a significant impact on the outcome. By detecting fallen workers, we can identify and pinpoint the location of employees in need, to provide urgent aid and assistance. By simply eliminating time spent on detecting and locating an injured person, the severity of the incident can be significantly reduced.

Talk to a Nokia expert

Please complete the form below.

The form is loading, please wait...