Customer success stories

How does Nokia help customers reach their industrial digitalization goals?

Learn how leading organizations across all industries are digitalizing their operations with our one platform for digital automation to improve worker safety, enhance quality and productivity, and reduce emissions and energy costs.

Our customers are implementing use cases and driving innovation at every level by leveraging the power of Nokia private wireless and Wi-Fi connectivity, industrial applications and devices, and a mission-critical industrial edge.

Industrial digitalization customer stories

Industrial edge - private wireless - applications - devices

Powering advanced robotics in logistics

Cainiao Smart Logistics Network Ltd, owned by Chinese multinational technology company Alibaba, uses advanced robotic systems for its smart logistics network warehouse operations. Operating in one of the largest and most competitive logistics vertical markets in the world, it has partnered with Nokia to develop digital transformation solutions to enhance efficiencies, reduce costs, and boost core competitiveness.

Nokia's industrial-grade private wireless solutions are advancing Industry 4.0 in logistics. For Cainiao, its mission-critical wireless connectivity requirements for its automated guided vehicles are enabled by Nokia's industrial-grade private wireless network.

Nokia's solution has transformed Cainiao's capabilities to drive robust inter-cell switch performance, powers rapid terminal mobility support and significantly reduces latency. The result? A next-generation private network that is safe, stable, efficient, and, crucially, designed for the Fourth Industrial Revolution.

Accelerating 5G connectivity where it is needed most

Pushing the boundaries of next-gen technology, Area X.O is a state-of-the-art R&D complex in Ottawa. Set up to experiment with and prove technologies across many sectors, it solves problems that matter to people today while simultaneously creating solutions for the future.

Nokia is a long-term partner of Area X.O, which is led by Invest Ottawa. Nokia plays a significant role in the Area X.O 5G Mobile Command Center, which is pioneering ways to provide reliable and secure wireless connectivity in areas without connectivity. As well as supporting emergency responders in locations where connectivity is limited but vital, it also provides cutting-edge, connected technologies to communities and businesses in remote areas.

Using Nokia Drone Networks, satellite communications and mobile command centers, the partnership between Area X.O and Nokia is pioneering 5G innovation where it is needed most.

Industry-leading connectivity at Helsinki Airport

With Helsinki Airport experiencing a rise in the number of passengers and air traffic, its owners Finavia had two objectives it wanted to meet: a streamlined passenger experience and effective operational efficiency across critical services. So Finavia teamed up with Edzcom and Nokia to bring next-generation connectivity to the airport.

Edzcom’s deployed Nokia’s private LTE network. It powers Helsinki Airport’s business-critical operations, from retail outlets to airlines, from runway communications to marshal services, from baggage clearance to de-icing aircraft. Prior to embracing the single, multi-service network, the airport would experience connectivity issues across essential operations such as uploading engine data, measuring runway temperature, and collecting wind speeds. Now, that’s a thing of the past.

With millions of passengers and thousands of employees, only the highest levels of operational efficiency will do. The collaboration between Nokia, Edzcom, and Finavia has increased efficiencies and reduced costs while enhancing safety.

Driving the digitalization of construction sites

Nokia is part of a groundbreaking consortium that has developed a data-driven management platform that enhances the connected technology required for smart building. Nokia, Kone, YIT, Caverion, Halton, VTT, Netox, Wirepas, Aiforsite, and Unseen have collaborated to produce KEKO, which brings together all building data onto a single platform.

KEKO addresses the challenge of real-time access to data in the building industry. Piloted at a YIT construction site in Tampere, Finland, KEKO provides access to workers, subcontractors, and management both on-site and off-site. Workers on-site can access the platform via the latest digitally connected tools, while remote construction management can access the platform wherever they are based.

Nokia private wireless connectivity secures reliable data sharing, while Nokia Digital Automation Cloud (DAC) provides connectivity and edge computing capabilities for secure and reliable data utilization. Fast, reliable, and intelligent, KEKO improved lead times at the pilot site by up to 50 percent. Ultimately, KEKO will make construction sites safer, streamline communications, improve efficiencies by reducing wastage, and get work completed faster and more cost-effectively.

Delivering reliable connectivity in remote mining

Mining requires reliable connectivity to keep workers safe and deliver critical data analysis.However, remote conditions make communication with teams a challenge becauseconnectivity can be unreliable. However, this may be a thing of the past after Nokia partnerAqura created a solution that delivers high-capacity communications to mining sites.

Being remote is no longer a disadvantage. Aqura's Autonomous Rapid Communications (ARC) platform is built on Nokia's private LTE solution. The portable platform is deployed quickly and set up in hours, and provides mining operations with reliable connectivity and edge compute capabilities. It meets data processing demands in harsh conditions and enables instant communications between operations centers and remote areas.

Nokia and Aqura's pioneering partnership is at the forefront of digital transformation solutions in mining. ARC not only makes reliable communications a reality in remote areas where once it was thought impossible, but the next-generation connectivity enhances decision-making by processing data locally. Nokia is proud to be making the future of mining operations safer, more efficient, and cost-effective.

Making the connected digital mine a reality

Boliden Kevitsa is a major multimetal open mine in Lapland, northern Finland. The location is remote, and conditions are harsh, with temperatures falling as low as -26°C. Such an environment requires state-of-the-art continuous monitoring and remote operations to improve mining efficiency and keep workers safe.

Partnerships are key for innovation and advancing technology. So Nokia has teamed up with Edzcom to deliver robust, reliable, and secure connectivity to the Boliden Kevitsa mine. Nokia and Edzcom have ensured mission-critical applications run smoothly in extreme conditions by creating a local and geo-redundant solution for a low-latency communications network.

The purpose-designed network connects all assets and people in a single private network, delivering high-capacity connectivity that enables automation, remote operation, and monitoring . Resulting in safer working conditions and reliable performance, even in some of the planet’s toughest working conditions.

Transforming the future of mining operations

Its innovative autonomous haulage technology is taking the capabilities of mining trucks to the next level. Komatsu’s fleet is remotely operated and can run autonomously around the clock, with clear benefits.

Komatsu fleet runs on its Autonomous Haulage System. It is powered by Nokia’s 4.9G/LTE, bringing wide network coverage to deliver mobile connectivity and support next-generation mining applications. Together, Komatsu and Nokia are transforming mining operations through improved safety, increased productivity, enhanced reliability, and greater efficiency.

Nokia’s private network supports mission-critical applications. By providing high-capacity, low-latency, high-reliability, and extensive network coverage, it enables Komatsu to collect sensor data, upstream video transmission, and remotely control the trucks. Simply, it is delivering the mobile broadband connectivity needed to take mining into a new era.

Revolutionising British Sugar's manufacturing with Nokia's Private 4G Network

British Sugar, in collaboration with Virgin Media O2 Business and strategic partner Nokia, has implemented innovative private mobile network, spanning multiple factories in a significant 'Factories of the Future' transformation. Nokia's secure, low-latency Digital Automation Cloud (DAC) is at the core of the custom-built O2 4G network, linking British Sugar's facilities across three counties in the UK.

This advanced connectivity enables the integration of Industry 4.0 technologies, artificial intelligence (AI), robotics and drones, revolutionizing the sugar production process. The 4G private network, a result of a seven-year partnership with Virgin Media O2 Business, ensures uninterrupted connectivity for over 15 different digital manufacturing use cases.

Designed to be future-ready and easily upgradable to 5G, the initiative positions British Sugar at the forefront of Industry 4.0, enhancing efficiency, reducing downtime and fostering sustainable production practices.

An industry-first 5G smart factory in Latin America

The Brazilian agricultural machinery manufacturing giant Jacto has taken a vital first step towards realizing its 5G Smart Factory ambitions. It has selected Nokia to deploy the first industrial-grade private wireless 4.9G/LTE & 5G private wireless network for the agricultural machinery industry anywhere in Latin America.

Jacto is now set to unleash the incredible transformational power of connectivity. It is collaborating with Nokia to build a new 96,000 square meter state-of-the-art 5G Smart Factory in Pompeia. This will house a cutting-edge automated painting system and enable autonomous vehicle handling and an automated storage system. An advanced training center will also be housed on the site.

Nokia is delighted to have been chosen to deliver the robust, secure, predictable and pervasive wireless coverage that Jacto needs to pursue Industry 4.0 excellence.

Nokia and MiR transforming manufacturing with 5G connectivity

In collaboration with Nokia and Mobile Industrial Robots (MiR), Aalborg University's Smart Production 5G Lab is showcasing the capabilities of industrial automation. This cutting-edge facility serves as a testbed for groundbreaking use cases, notably demonstrating the remote fleet management of Autonomous Mobile Robots (AMRs) over a private 5G network, backed by Nokia 5G small cell networks and local edge computing.

The 5G ACIA-approved testbed showcases two key use cases: Standard AMR operation over 5G and cloud-based AMR operation. In the first scenario, AMRs self-navigate in standard mode, demonstrating seamless control and communication over a private 5G network with round-trip latency below 35 milliseconds and satisfactory throughput.

The second use case explores cloud-based intelligent mode, where AMRs rely on local edge cloud servers for fleet management, simplifying operations while maintaining satisfactory 5G performance. This demonstration underscores the pivotal role of 5G in reshaping manufacturing processes, offering manufacturers the performance needed for their digital transformation journeys.

Enabling smart city services in Dubai

Nokia’s private LTE network will deliver secure high-speed broadband, supporting crucial aspects of public safety and security in Dubai.

The development of smart cities is at the forefront of the UAE's long-term vision. Smart cities will provide greater public sector efficiencies, reduce costs, drive sustainability, enhance public services, increase digital equity and increase safety. The next-generation 5G network capabilities will allow Nedaa to provide dedicated segment-related solutions across multiple industries.

Nokia's partnership with Nedaa already supports mission-critical networks. The introduction of the 5G network takes the collaboration to the next level, helping Nedaa deliver enhanced services across Dubai. From immersive applications for first responders to connected and automated vehicles, Nokia's technology is helping to push the boundaries of what’s possible in Dubai.

Tsunami warning sytem in Japan

The Japanese city of Sendai and Nokia have worked together to create a tsunami warning system based on Nokia Drone Networks, which operates even when the public network is down.

In March 2011, a massive earthquake in the Pacific Ocean triggered a devastating tsunami. An evacuation alert sent a warning only eight to ten minutes before the tsunami struck the city of Sendai, on the north-east coast of Japan. Waves reached 10 meters high and travelled 5km inland. Tragically, almost 1,000 people lost their lives in the city.

To improve alerts and rescue operations, the city uses Nokia's connected drone technology, which operates on a secure, reliable private wireless network. The drones fly in fully automated swarms to raise the alarm and keep the people providing evacuation alerts protected. When the tsunami reaches land, drones with thermal cameras will aid the rescue and evacuation phase.

Industry-leading network slicing in Germany

The Port of Hamburg is Germany’s largest port, and sits on the river Elbe, 110km from the North Sea. The third-largest container port in Europe, it handles millions of containers every year, and thousands of trucks a day, employs almost 2,000 people, and is home to around 100,000 mobile sensors.

This volume of industry, mixed with a vast collection of roads, bridges, waterways, and railways, needs innovative connectivity solutions to deliver operational efficiency. The Hamburg Port Authority, Nokia, and Deutsche Telekom collaborated on a field trial to deploy a 5G network with next-generation slicing functionality. This pioneering approach saw one network slice created for three use cases: ultra-reliable and low-latency communications; enhanced mobile broadband; massive machine-type communication.

Implementing a digital transformation project in a complex industrial environment is challenging. However, the field trial significantly improved productivity at the Port of Hamburg and delivered environmental and social benefits.

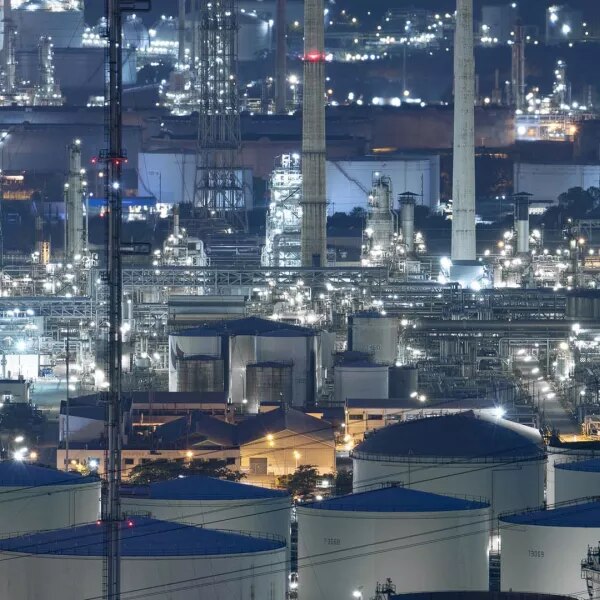

A next-generation port in Finland

The Port of Oulu covers three harbors in Oulu, on the north-west coast of Finland.It is a complex environment, with an average of 3m tons of cargo shipped yearly and facilities for oil, chemicals, and container freight. The digital transformation of such a challenging industrial operation requires specialist knowledge, and that’s where Nokia and Ukkoverkot come in.

The partnership between Nokia and Ukkoverkot Edzcom spearheads the Port Oulu Smarter digitalization project. Introducing a private wireless network brings reliable mobile broadband connectivity to the port. Through sensors and cameras, it connects machines and people across the port, with cranes, lifts, and vehicles all receiving and transmitting data to a single, easily-accessible platform.

The digital transformation has improved efficiencies across the port, benefiting customers, partners, enterprises, and local businesses.

Ruggedized industrial devices for ports

Part of the Cargotec Corporation, Kalmar delivers innovative and eco-efficient cargo-handling equipment, automated terminal solutions, software, and support services for ports worldwide.

It operates a groundbreaking testing center in Finland, with the goal of advancing port automation technologies. This wouldn’t be possible without collaboration. So Kalmar has partnered with Telia, Digita, and Nokia to optimize communications and connectivity. Using Nokia's Digital Automation Cloud (DAC), they implement end-to-end industrial-grade private 4G and 5G wireless networks to power greater port automation by offering low latency and pervasive connectivity.

Integrated with Nokia’s ruggedized industrial user equipment that operates in harsh and remote environments such as ports, the technology connects people and machines across complex industrial environments. As well as improving operational and production efficiency, advanced automation reduces wastage, carbon emissions, and slow-downs at ports.

Optimizing marine freight operations

One of the largest container ports in the US, the Port of Tacoma is spread across 2,500 acres and is home to five major container terminals. One of those terminals, Husky Terminal and Stevedoring, turned to Nokia to optimize freight operations. Nokia deployed the private 4.9G/LTE network to support the terminal’s digital upgrade.

The next-generation technology removes the performance and productivity issues for mission-critical applications traditionally encountered with Wi-Fi. It moves the port to a cloud-based terminal operating system (TOS) that can be accessed remotely from anywhere.The network leverages Nokia industry-grade Digital Automation Cloud (DAC), increasing capacity supported by secure low latency connectivity across Husky Terminal’s 115-acre container yard.

The transformation means the regular downtimes and disconnections previously experienced over Wi-Fi are a thing of the past. In its place are future-proofed digital services that have reduced costs, streamlined operations, and surpassed customer expectations.

Arena 2036 emerges as a blueprint for 5G innovation

Arena 2036, located in Vaihingen, Germany, stands as a cutting-edge 5G research campus dedicated to testing diverse use cases, ranging from video applications and robotics to self-driving vehicles. Collaborating closely with private sector businesses, a team of researchers from the University of Stuttgart operates within the facility, exploring the seamless integration of 5G into various domains.

A pivotal focus of 5G applications is its capability to operate large machines and equipment wirelessly. In a groundbreaking partnership, Nokia and Bosch are actively engaged in optimizing always-on communication within Arena 2036. This involves deploying multiple antennas throughout the facility to ensure uninterrupted communication between control units and machinery.

Among the forefront technologies being tested at Arena 2036 are autonomous vehicles, relying heavily on low latency and real-time data transmission. Bosch harnesses 5G capabilities to develop Automated Guided Vehicles equipped with cameras that leverage the network for recognizing and reacting to their surroundings. To step into Arena 2036 is to experience the future of communications and enterprise, where innovation converges with practical applications.

Delivering efficiency, scalability, and security at Nokia smart factory

Nokia's High Accuracy Indoor Positioning (HAIP) is reshaping operations at the Chennai smart factory, covering an expansive 4,000 square meters and tagging over 400 critical assets. HAIP's precision location capabilities drive digitalization and automation, optimizing manufacturing processes and transforming efficiency and productivity at the facility.

HAIP's real-time tracking and geo-mapping functionalities empower diverse applications, from streamlining sorting and layout to enhancing safety during Automated Guided Vehicles (AGVs) manoeuvres. Seamlessly integrated with Nokia Digital Automation Cloud (DAC), the solution ensures both security and scalability.

The impact of this transformation is significant, paving the way for heightened productivity and safety. Nokia's HAIP emerges as a game-changer, propelling the Chennai smart factory into the forefront of Industry 4.0 innovation.

Connecting workers, vehicles, and machines in a Mexican port

The industrial-grade LTE private network is the first to be used in a maritime terminal in Mexico. The state-of-the-art technology is deployed at the APM Terminals terminal in Puerto Progreso in Yucatán. Using 4.9G LTE, it delivers pervasive high-bandwidth, low- latency connectivity across the terminal’s 11.5 hectares.

The private network is a significant step in the terminal’s digital transformation journey. It connects hundreds of workers, sensors, vehicles, and equipment across the terminal. With security and reliability at its heart, the network allows APM Terminals to expand its digitalization and automation strategy.

The network is based on Nokia’s (DAC) platform, a high- performance,end-to-end private wireless network and edge computing platform. Built for the future, DAC enables APM Terminals to introduce new capabilities, such as remote and autonomous crane operations at the terminal.

An industry first in chemicals

A global leader in the chemical industry, BASF operates the largest chemical factory in southern Europe. To improve safety, drive production efficiency and ensure future-proofing for Industry 4.0, BASF implemented the first 5G private network in Spain and the first in the chemical industry.

Nokia sees strategic partnerships as key to providing real value for customers. So, to deploy the 5G network at BASF, Nokia collaborated with Spanish wireless telecommunications infrastructure and services company Cellnex.

The mission-critical results were immediate. The low network latency enables automated vehicles to be operated safely across the entire site. It has also improved worker safety by installing tracking devices on workers’ helmets with a safety button that pinpoints their precise location. The high-performing network means workers can access augmented reality on devices that scan issues such as broken pipes, and immediately access real-time information to fix the problem.

Upgrading plant connectivity across 20 square miles

In the vast landscape of Dow's Freeport site, the largest integrated chemical manufacturing complex in the Western Hemisphere, a digital program is reshaping plant maintenance. Dow has integrated technology to enhance safety, agility, and reliability across its 40 production plants spanning 20 square miles.

At the heart of this transformation is Dow's adoption of a private LTE network, a cornerstone in its digitalization strategy. It worked in collaboration with Kyndryl to establish the requirements for the entire complex. This technological leap empowers on-the-ground technicians with real-time connectivity through tablets and smartphones, replacing cumbersome paper-based methods. Streamlined communication facilitates efficient decision-making, particularly in a complex and expansive industrial setting.

Nokia and Kyndryl expanded their global network and edge computing partnership. The three-year agreement includes plans to co-innovate and accelerate the deployment of flexible, reliable, and secure LTE and 5G private wireless connectivity services and Industry 4.0 solutions.

Cleaning up the oceans with wireless connectivity

The international non-profit organization has partnered with Nokia to develop and scale technologies that tackle the enormous environmental impact of plastic in our oceans. In the last decade, more plastic has been produced than in the previous century, making up 80 percent% of all marine pollution.

Nokia deploys private wireless connectivity, network edge equipment, and analytics to Ocean Cleanup. Nokia’s high-performance, end-to-end private wireless networking and edge computing platform, Digital Automation Cloud (DAC), and Nokia MX Industrial Edge (MXIE) will help navigate operations such as plastic harvesting in the Great Pacific Garbage Patch.

From subsea optical fiber networks to acoustic sending technology, Nokia is committed to using its technology to relieve pressure on the environment and natural ecosystems.

First-ever 5G port network in Latin America

The partnership will deliver South America’s first-ever 5G private wireless port network, at Santos Port Brasil Terminal Portuário (BTP). Brazil’s largest port, BTP connects with over 600 ports in 125 countries and handles over 100 million tons of cargo each year.

The private 5G network will drive the digital transformation of BTP’s container terminal operations in Santos. Deployed by Brazilian mobile carrier TIM, and based on Nokia’s leading-edge network equipment and solutions, the pioneering technology will improve operational efficiency, significantly boost equipment connectivity, and streamline communications among the 1,400 terminal employees.

Enabling real-time monitoring of equipment - remotely, from anywhere - improves the productivity and safety of operational activities, including using cranes. Nokia is proud to work with BTP to stay at the cutting edge of port and terminal operations across Latin America.

Breaking new ground in port operations in San Antonio

The San Antonio Terminal Internacional (STI) was transported to the future with the addition of Nokia’s private network. The private wireless network uses 4.9G LTE to deliver low latency and reliable connectivity across the entire site, with the technology based on the Nokia Digital Automation Cloud (DAC) platform.

STI is Chile’s main port terminal and is of significant importance in South America. To maintain its competitiveness in a challenging marketplace, STI’s business-critical objective is to optimize its operation and service through a digital transformation. Nokia’s state-of-the-art network powers this transformation, enabling remote and autonomous operations and faster,more reliable, and secure data transmission.

An industry-first in Colombian port terminal

Nokia and Claro have partnered to deliver the first industrial-grade private 4.9G wireless network in a maritime terminal in Colombia. The Sociedad Portuaria Puerto Bahía, on Colombia’s Caribbean coast, is blazing a trail as the first multipurpose terminal to adopt a private 4G technology in Latin America.

Puerto Bahía is the largest private hydrocarbon terminal in Colombia. It also handles general cargo and provides logistics and offshore exploration services. Connecting such an asset-heavy industrial site is challenging. Still, the private network - powered by Claro and using the Nokia Digital Automation Cloud (DAC) platform - connects hundreds of workers, sensors, vehicles, and equipment. This includes tracking up to 20,000 vehicles and connecting cranes in docks and yards.

Puerto Bahía is optimizing operations and saving costs by improving network predictability across the whole site. The technology is built to be adaptable, allowing new use cases to be added throughout the digital transformation roadmap.

Unleashing the factories of the future with 5G connectivity

Nokia, Bosch and Rohde & Schwarz collaborated to showcase the transformative capabilities of industrial automation through a 5G standalone private network. Conducted at Bosch's Industry 4.0 Lighthouse Factory in Stuttgart-Feuerbach, Germany, the demonstration showcases the immense potential of 5G in real-world manufacturing environments.

Nokia's Digital Automation Cloud (DAC) comprising small cells and an edge cloud server, formed the backbone of the high-performance 5G private network. Bosch Rexroth's Active Shuttle, a self-navigating autonomous transport system, seamlessly connects to the network, receiving routing instructions for efficient material delivery on the factory floor.

This pioneering initiative shows how 5G can deliver the performance, reliability, and quality of service required to automate and digitize manufacturing operations. The test cases presented include wireless coverage assessments, signal interference measurements, throughput evaluations, and latency measurements, all demonstrating the tangible benefits of 5G in revolutionizing the factory of the future.

Changing how consumer goods are made in Turkey

It’s new 5G private wireless network is helping it to radically modernize productivity and transform efficiency while improving worker safety across its Çayırova washing machine manufacturing plant.

The secret is expert collaboration. Arçelik worked closely with Türk Telekom to deploy a high-performance Nokia Digital Automation Cloud, providing ubiquitous 5G private wireless connectivity across its factory operations and enabling a new generation of advanced Industry 4.0 and automation solutions. AGV (Autonomous Guided Vehicle) performance has been unleashed, assets can now be tracked across the site in real-time and new video analytics-based applications make the site a much safer place to work.

In another pioneering move, the manufacturing powerhouse has identified a 30 further transformational use-cases that can be enabled by its new 5G private wireless network. These will together accelerate the company’s smart factory strategy and deliver payback at the lightning speeds every competitive operation needs in a tough global economy.

Transforming the UK’s first 5G port

Every year, the Port of Southampton, on the UK’s south coast, handles over £450bn of UK exports, transports nearly 600,000 vehicles, and welcomes over 1m cruise passengers. Simply, it is critical to the global economy. But, like any big business, it needed to evolve digitally to remain competitive.

Associated British Ports, which runs the Port of Southampton, brought in Nokia and Verizon to create a state-of-the-art smart port. Nokia’s and Verizon’s 5G platform provides a low-latency and secure private network connection. The network drives efficiencies, flexibility, and security while keeping the many thousands of people who work at the port connected through ultra-fast communications across all terminals.

From automated drone flights to utilizing computer vision, and from developing simulations of port operations with machine learning to providing real-time product information, the Port of Southampton is truly a global leader in innovation.

Simplifying processes in the chemical industry

The manufacturer is looking to the future at its chemical plant in Ottmarsheim, France. There, it creates technical plastics, industrial fibers, and elevated coatings across automotive, textile and consumer goods industries. Butachiminie wanted to simplify processes, improve security, embrace sustainability and future-proof its production chain to maintain an advantage in a competitive marketplace.

To achieve this, Butachiminie turned to Industry 4.0. It chose Nokia and Orange to modernize its facilities with a private LTE network, and the partnership is turning the plant into a Factory of the Future.

The low-latency 4G LTE network has delivered a catalog of future-proofed benefits. Connected video surveillance monitors plant access and the chemical production processes, while push-to-talk and push-to-video connectivity facilitate reliable communication between on-site workers and remote experts. On top of that, IoT sensors enable real-time condition monitoring and management of critical assets, as well as asset and worker localization.

Driving innovation at a smart factory in Finland

A world-leading producer of cutting-edge lifting solutions, Konecranes is committed to constantly innovating. With over 16,000 employees in 50 countries and 15,000 remote connections, Konecranes opened a smart factory at Hyvinkä to explore opportunities for technology innovation, development, evaluation, and deployment. Hyvinkä allows Konecranes to realize the enormous potential of wireless connectivity.

By doing so, it can continue to meet the digital transformation demands of its customers at ports, terminals, shipyards, and factories. To build the capabilities for Industry 4.0 and power automation, Hyvinkä leverages Nokia’s and Edzcom’s next-generation 5G standalone private network.

Nokia Digital Automation Cloud (DAC) 5G StandaloneSA private wireless network powers Konecranes’ technology evolution. With improved scalability, latency, and bandwidth, Konecranes offers its customers leading-edge connectivity solutions to create an ecosystem of connected machines, people, and devices. The result? Its customers’ operations are more efficient, more productive, safer, and future-proofed.

Deploying Digital Automation Cloud in Seattle

A full-service provider of terminal operating system solutions, Tideworks Technology turned to Nokia to transform SSA Marine Terminal 5 at the Port of Seattle. Nokia introduced Digital Automation Cloud (DAC), taking cable-free port and intermodal terminal operations into a new era.

DAC enables high-performance, industrial-grade LTE/5G private wireless networking. The ultra-reliable digital automation platform reduces the complexity of the port environment and increases efficiency, worker safety, and terminal handling productivity. Seamless communication across all logistics parties is vital to the smooth operation of a port, and private wireless facilitates this by connecting the terminal’s operations and machinery, including cranes, vehicles, and lifts.

Ports can be challenging sites to operate at. In this unpredictable environment, Nokia DAC incorporates ruggedized digital devices for terminal-wide communications and applications to ensure no communication breakdown.

Digitalizing HaminaKotka port with private LTE

Port operator Steveco has embraced a high-capacity mobile broadband network to power a digital transformation at the Port of HaminaKotka in Finland. Nokia and Edzcom have collaborated to provide a private LTE network to the port, with the dedicated low-latency network driving efficiencies across operations.

The network enables connectivity for sensors, vehicles, robots, and workers.Remote mobile access to mission-critical applications and information has improved situational awareness of port logistics and container handling and enhanced security. Meanwhile, connected cameras provide reliable real-time video streaming, advanced data analytics, and asset tracking.

The digital transformation isn’t only for now. It is also for the future, with Nokia’s technology solutions helping Steveco to embrace the Internet of Things, automation, AI, and machine learning to boost productivity and reduce costs.

Accelerating digital transformation in Latin America

The alliance will bring Nokia’s industrial-grade private wireless network and digitalization platform solutions to enterprises across Latin America. It will be focused on four industries showing significant promise in Hispanic America: ports, mining, energy, and manufacturing.

The alliance will power South American industries into the future of Industry 4.0. Combining Nokia’s leading industrial-grade private wireless solutions with Teléfonica’s growing B2B solutions and services footprint across Latin America,the partnership will help businesses across the region to compete globally.

Companies can leverage LTE & 5G private wireless networks, which deliver a more pervasive broadband connectivity with lower latency, greater predictability, and higher security. Nokia is proud to embark on a game-changing alliance to boost digital transformation across Latin America.

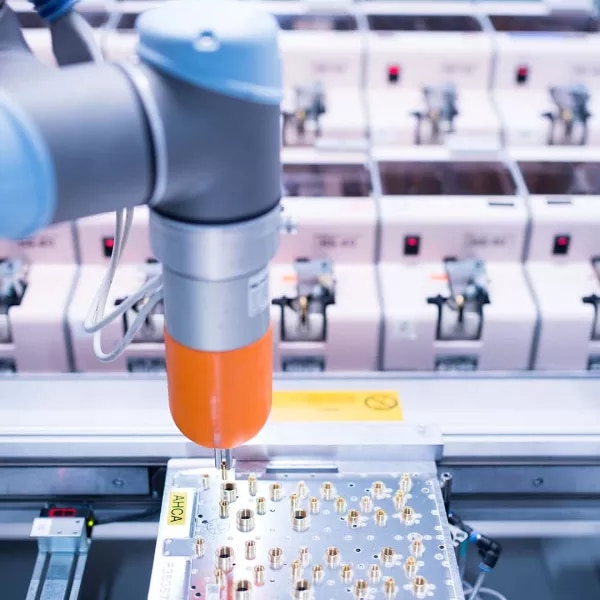

Changing what’s possible in manufacturing with Omron and NTT Docomo

Nokia’s 5G innovations and reliable connectivity are being used by Omron and NTT Docomo to take the manufacturing sector to the next level. The companies are working together to rethink what efficient manufacturing looks like. That means layout-free production lines that can manufacture variations of multiple products at the same time.

It is Nokia’s high-speed, low-latency private 5G network that makes such a leap possible. Not only is 5G making the manufacturing environment more flexible and efficient, but it is also enabling the use of artificial intelligence (AI) and Internet of Things (IoT) devices.

The integration of 5G, AI, and IoT empowers predictive maintenance, offering real-time insights and guidance to operators. The result is an ecosystem where connectivity serves as the backbone, taking manufacturing to the next level of efficiency and adaptability.

Nokia’s 5G transforms aviation inspections with ‘Virtual Table’

Nokia and Lufthansa Technik, a leading provider of aircraft services, have implemented a 5G industrial-grade private wireless network to enhance a project focused on remote engine parts inspection for civil aviation customers.

Through Lufthansa Technik's 'Virtual Table Inspection' at its Hamburg facility, the 5G network eliminates the need for physical customer presence, providing seamless video access to the engine overhaul shop floor. The 'Virtual Table Inspection' allows experts to assess engine repair decisions, replacing the previous requirement for customers to travel to Hamburg for in-person inspections.

The 5G network ensures a reliable stream as it seamlessly transitions across the hangar, offering stable, high-quality video streams for detailed inspections. This innovative use of 5G technology enhances efficiency, customer experience and collaboration between Nokia and Lufthansa Technik.

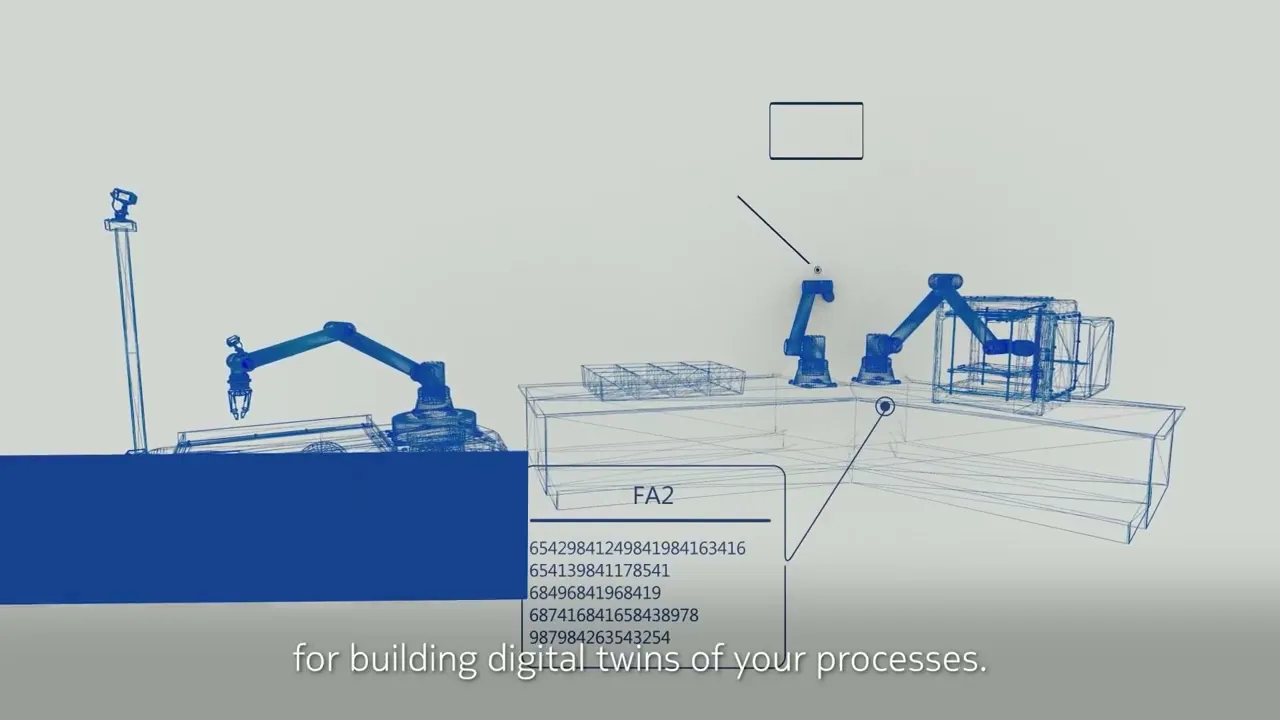

How Digital Automation Cloud powers Nokia’s ‘factory of the future’

Nokia's Oulu factory, often referred to as its "factory of the future," stands as a testament to the transformative impact of technology on the manufacturing industry. Central to this revolution is the implementation of the Nokia Digital Automation Cloud (DAC), a seamlessly integrated, plug-and-play platform that revolutionizes the factory's operational landscape.

Within the DAC framework, private wireless access points and a local edge server are seamlessly integrated. This not only provides pervasive coverage but also built-in redundancy. This ensures that even the most critical applications can operate wirelessly, marking a significant leap in operational flexibility.

The incorporation of Automated Guided Vehicles (AGVs), real-time monitoring, and Digital Twin capabilities showcases DAC's pivotal role in facilitating dynamic production layouts. This transformative approach has led to substantial cost reductions and a noteworthy increase in overall productivity. The transition to LTE connectivity has eliminated previous network restrictions. This optimization has not only enhanced the efficiency of AGVs routes but has also facilitated a seamless and efficient material feed to the production line.

Providing equal access to Fairmont students

Connectivity is key to education, but the pandemic showed that not all students have equal access. Collinsville Community Unit School District 10 responded to the digital divide by partnering with IT solutions provider STEPcg to construct a private LTE network that delivers internet connectivity to around 500 students in the Fairmont City and State Park communities.

Utilizing technologies from Nokia and Cambium Networks, the network is among the first in the US built by a school district. The network’s centerpiece is an LTE Broadband Tower constructed at an Elementary School, and includes four Nokia CBRS microcell installations that provide approximately four square miles of coverage.

Now, students across State Park and Fairmont City have equal access to safe and reliable high-speed connectivity from home. Much work is needed to close the digital divide across the US, but Nokia's innovative industrial-grade private wireless is pointing the way.

Connecting underserved students in Texas

The pandemic shone a light on how the digital divide can severely impact students from underserved communities. So when the Southwest Independent School District (SWISD) in Texas found that 11 percent of its pupils had inadequate broadband access to support its digital learning efforts, it acted quickly. SWISD, Bexar County, Wytec International, and Nokia collaborated to develop and roll out a private LTE network to better support rural and underserved communities.

Nokia Digital Automation Cloud (DAC) platform delivers reliable, secure, high-performance private wireless connectivity. This technology was the perfect solution to providing access for all. Home-based students could access the network through an LTE small cell, connected by a short-haul microwave link to the Nokia DAC core location at the school campus.

Nokia DAC's magic is its versatility. A scalable, compact plug-and-play platform, it is fast to deploy and efficiently processes data on-site. Nokia was delighted to be part of a collaborative effort that helped underserved students through an especially challenging time.

Letting port data do the heavy lifting in Finland

The Port of Kokkola is the third-largest port in Finland, looking out to the Baltic Sea. Divided into three ports - Deep, General, and Silverstone - it houses industry across land, rail, shipping, warehousing, logistics, and terminals.

So, how do you successfully connect three ports, spanning 580 hectares? Using Nokia’s private wireless LTE/4.9G/LTE connectivity technology, Edzcom designed a network to improve efficiency and sustainability across the three ports. Mission-critical information and activities such as real-time load monitoring, lighting, water usage, energy and fuel metering, security, and gate control are now accessible and shareable from one control room or remotely on mobile devices.

The game-changing connectivity means production efficiency has improved, and costs have been reduced for the companies using the port. For example, real-time information loading enables ships to arrive at the port on time when there is a free slot at the quay, rather than waiting for a space, saving fuel costs and reducing the environmental impact. In the future, Port of Kokkola will deploy 5G to support a wider range of advanced use cases.

Transforming factory automation and AMR operations at Arena 2036

In the innovative setting of Arena 2036, Omron's autonomous mobile robots (AMRs) seamlessly operate on Nokia's 5G standalone private wireless network. Mobile robots in manufacturing require predictable performance from wireless networks to carry out their tasks. A connection delay or failure can shut down an entire facility.

Omron leverages Nokia’s private 5G network. This showcases the capabilities of AMRs in settings with reliable, high-speed connectivity and low latency. The predictable performance ensures uninterrupted connectivity for optimal task allocation.

This collaboration signifies a significant leap in the realm of wireless automation, where disruptions during transitions between access points or in areas with poor coverage are mitigated.

Nokia delivers 5G private wireless network in Japan

Nippon Steel is partnering with Nokia to enhance manufacturing efficiency through the installation of a private LTE network. This network facilitates 5G connectivity between various devices such as sensors, smartphones, and cameras, enabling remote monitoring and support.

The objective is to improve safety, minimize downtime and enhance maintenance productivity. The transition to 5G opens up possibilities for additional use cases, including autonomous factory vehicles and high-definition video monitoring. The collaboration highlights the potential of utilizing private spectrum for IoT adoption, showcasing how industries can leverage innovative solutions to advance workplace safety and overall operational efficiency.

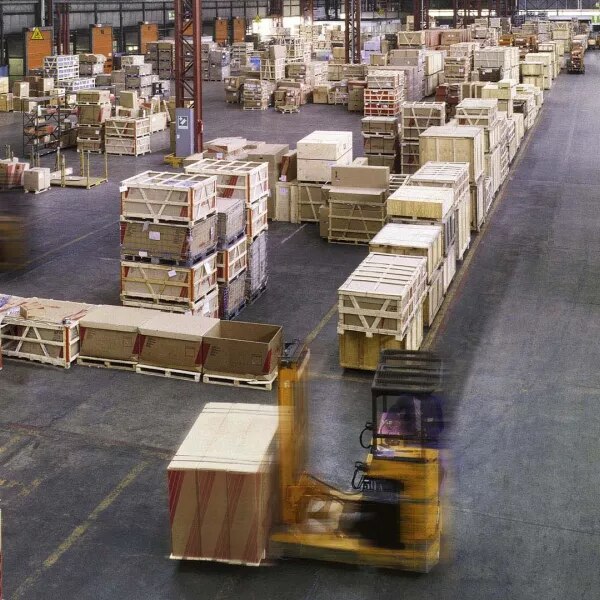

Improving warehouse efficiencies with a Private LTE Network

Graybar, a Fortune 500 company, is a leading North American distributor of electrical, communications, data networking and industrial products. With over 325 locations, a streamlined warehouse operation is key to success, but challenges around connectivity meant it was falling short of where it wanted to be.

Graybar teamed up with Nokia to power its warehouse digital transformation, utilizing Nokia Digital Automation Cloud (DAC) private wireless solution. The aim: next-generation connectivity that would get products and materials out of its warehouses as efficiently, safely, and cost-effectively as possible, improving customer service and enhancing operations for its warehouse workers.

Previously, Graybar experienced regular connectivity interruptions, which resulted in the warehouse grinding to a halt. It also suffered from connectivity dead spots, which would change location daily. By introducing DAC, all dead spots were eliminated, and Graybar enjoys consistent wireless connectivity throughout the warehouse. The result? Faster speeds, more robust security features, and a seamless operator experience – all while saving costs.

Empowering YOFC’s digital transformation to a smart factory

A global manufacturer of optical cables, YOFC required a business-critical digital transformation of its Hanchuan campus in east-central China. Its goal was to drive production efficiency and business competitiveness, and it wanted to do so by deploying a private network at the heart of the campus.

YOFC partnered with Nokia Shanghai Bell, and used Nokia Digital Automation Cloud to develop a smart factory solution. By establishing its reliable and efficient low-latency wireless network, Nokia transformed the Hanchuan campus into a state-of-the-art environment that can accommodate emerging smart factory applications, systems, and processes. Simply, Nokia has future-proofed YOFC’s campus.

The transformation has enabled seamless connection throughout the site, powering the intelligent management of smart devices and production equipment. The result? Improved production efficiency and quality, increased security, and reliable stability across all of YOSF’s operations.

Integrate technology with tangible business benefits

Lufthansa Industry Solutions is an IT consultancy within the Lufthansa Group, one of the world’s largest aviation companies. The company’s mission is to understand how advanced new technologies can benefit the Lufthansa Group and other industries - determining the best ways to implement these technologies and addressing the business needs they can fulfill.

Lufthansa Industry Solutions has collaborated with Lufthansa Technik (also part of the Lufthansa Group), Nokia and other vendors as part of its mission to integrate technology with tangible business benefits, providing wireless connectivity in intricate environments.

Delivering connectivity in challenging environments in airports and aircraft facilities is a mission-critical challenge for Lufthansa Group. These facilities are often extremely large – airports the size of small cities and hangers covering tens if not hundreds of thousands of square meters.

Changing how consumer goods are made in Turkey

It’s new 5G private wireless network is helping it to radically modernize productivity and transform efficiency while improving worker safety across its Çayırova washing machine manufacturing plant.

The secret is expert collaboration. Arçelik worked closely with Türk Telekom to deploy a high-performance Nokia Digital Automation Cloud, providing ubiquitous 5G private wireless connectivity across its factory operations and enabling a new generation of advanced Industry 4.0 and automation solutions. AGV (Autonomous Guided Vehicle) performance has been unleashed, assets can now be tracked across the site in real-time and new video analytics-based applications make the site a much safer place to work.

In another pioneering move, the manufacturing powerhouse has identified a 30 further transformational use-cases that can be enabled by its new 5G private wireless network. These will together accelerate the company’s smart factory strategy and deliver payback at the lightning speeds every competitive operation needs in a tough global economy.

An industry-first 5G smart factory in Latin Amercia

The Brazilian agricultural machinery manufacturing giant Jacto has taken a vital first step towards realizing its 5G Smart Factory ambitions. It has selected Nokia to deploy the first industrial-grade private wireless 4.9G/LTE & 5G private wireless network for the agricultural machinery industry anywhere in Latin America.

Jacto is now set to unleash the incredible transformational power of connectivity. It is collaborating with Nokia to build a new 96,000 square meter state-of-the-art 5G Smart Factory in Pompeia. This will house a cutting-edge automated painting system and enable autonomous vehicle handling and an automated storage system. An advanced training center will also be housed on the site.

Nokia is delighted to have been chosen to deliver the robust, secure, predictable and pervasive wireless coverage that Jacto needs to pursue Industry 4.0 excellence.

Unleashing the factories of the future with 5G connectivity

Nokia, Bosch and Rohde & Schwarz collaborated to showcase the transformative capabilities of industrial automation through a 5G standalone private network. Conducted at Bosch's Industry 4.0 Lighthouse Factory in Stuttgart-Feuerbach, Germany, the demonstration showcases the immense potential of 5G in real-world manufacturing environments.

Nokia's Digital Automation Cloud (DAC) comprising small cells and an edge cloud server, formed the backbone of the high-performance 5G private network. Bosch Rexroth's Active Shuttle, a self-navigating autonomous transport system, seamlessly connects to the network, receiving routing instructions for efficient material delivery on the factory floor.

This pioneering initiative shows how 5G can deliver the performance, reliability, and quality of service required to automate and digitize manufacturing operations. The test cases presented include wireless coverage assessments, signal interference measurements, throughput evaluations, and latency measurements, all demonstrating the tangible benefits of 5G in revolutionizing the factory of the future.

How Digital Automation Cloud powers Nokia’s ‘factory of the future’

Nokia's Oulu factory, often referred to as its "factory of the future," stands as a testament to the transformative impact of technology on the manufacturing industry. Central to this revolution is the implementation of the Nokia Digital Automation Cloud (DAC), a seamlessly integrated, plug-and-play platform that revolutionizes the factory's operational landscape.

Within the DAC framework, private wireless access points and a local edge server are seamlessly integrated. This not only provides pervasive coverage but also built-in redundancy. This ensures that even the most critical applications can operate wirelessly, marking a significant leap in operational flexibility.

The incorporation of Automated Guided Vehicles (AGVs), real-time monitoring, and Digital Twin capabilities showcases DAC's pivotal role in facilitating dynamic production layouts. This transformative approach has led to substantial cost reductions and a noteworthy increase in overall productivity. The transition to LTE connectivity has eliminated previous network restrictions. This optimization has not only enhanced the efficiency of AGVs routes but has also facilitated a seamless and efficient material feed to the production line.

Arena 2036 emerges as a blueprint for 5G innovation

Arena 2036, located in Vaihingen, Germany, stands as a cutting-edge 5G research campus dedicated to testing diverse use cases, ranging from video applications and robotics to self-driving vehicles. Collaborating closely with private sector businesses, a team of researchers from the University of Stuttgart operates within the facility, exploring the seamless integration of 5G into various domains.

A pivotal focus of 5G applications is its capability to operate large machines and equipment wirelessly. In a groundbreaking partnership, Nokia and Bosch are actively engaged in optimizing always-on communication within Arena 2036. This involves deploying multiple antennas throughout the facility to ensure uninterrupted communication between control units and machinery.

Among the forefront technologies being tested at Arena 2036 are autonomous vehicles, relying heavily on low latency and real-time data transmission. Bosch harnesses 5G capabilities to develop Automated Guided Vehicles equipped with cameras that leverage the network for recognizing and reacting to their surroundings. To step into Arena 2036 is to experience the future of communications and enterprise, where innovation converges with practical applications.

Nokia and MiR transforming manufacturing with 5G connectivity

In collaboration with Nokia and Mobile Industrial Robots (MiR), Aalborg University's Smart Production 5G Lab is showcasing the capabilities of industrial automation. This cutting-edge facility serves as a testbed for groundbreaking use cases, notably demonstrating the remote fleet management of Autonomous Mobile Robots (AMRs) over a private 5G network, backed by Nokia 5G small cell networks and local edge computing.

The 5G ACIA-approved testbed showcases two key use cases: Standard AMR operation over 5G and cloud-based AMR operation. In the first scenario, AMRs self-navigate in standard mode, demonstrating seamless control and communication over a private 5G network with round-trip latency below 35 milliseconds and satisfactory throughput.

The second use case explores cloud-based intelligent mode, where AMRs rely on local edge cloud servers for fleet management, simplifying operations while maintaining satisfactory 5G performance. This demonstration underscores the pivotal role of 5G in reshaping manufacturing processes, offering manufacturers the performance needed for their digital transformation journeys.

Changing what’s possible in manufacturing with Omron and NTT Docomo

Nokia’s 5G innovations and reliable connectivity are being used by Omron and NTT Docomo to take the manufacturing sector to the next level. The companies are working together to rethink what efficient manufacturing looks like. That means layout-free production lines that can manufacture variations of multiple products at the same time.

It is Nokia’s high-speed, low-latency private 5G network that makes such a leap possible. Not only is 5G making the manufacturing environment more flexible and efficient, but it is also enabling the use of artificial intelligence (AI) and Internet of Things (IoT) devices.

The integration of 5G, AI, and IoT empowers predictive maintenance, offering real-time insights and guidance to operators. The result is an ecosystem where connectivity serves as the backbone, taking manufacturing to the next level of efficiency and adaptability.

Delivering efficiency, scalability, and security at Nokia smart factory

Nokia's High Accuracy Indoor Positioning (HAIP) is reshaping operations at the Chennai smart factory, covering an expansive 4,000 square meters and tagging over 400 critical assets. HAIP's precision location capabilities drive digitalization and automation, optimizing manufacturing processes and transforming efficiency and productivity at the facility.

HAIP's real-time tracking and geo-mapping functionalities empower diverse applications, from streamlining sorting and layout to enhancing safety during Automated Guided Vehicles (AGVs) manoeuvres. Seamlessly integrated with Nokia Digital Automation Cloud (DAC), the solution ensures both security and scalability.

The impact of this transformation is significant, paving the way for heightened productivity and safety. Nokia's HAIP emerges as a game-changer, propelling the Chennai smart factory into the forefront of Industry 4.0 innovation.

Transforming factory automation and AMR operations at Arena 2036

In the innovative setting of Arena 2036, Omron's autonomous mobile robots (AMRs) seamlessly operate on Nokia's 5G standalone private wireless network. Mobile robots in manufacturing require predictable performance from wireless networks to carry out their tasks. A connection delay or failure can shut down an entire facility.

Omron leverages Nokia’s private 5G network. This showcases the capabilities of AMRs in settings with reliable, high-speed connectivity and low latency. The predictable performance ensures uninterrupted connectivity for optimal task allocation.

This collaboration signifies a significant leap in the realm of wireless automation, where disruptions during transitions between access points or in areas with poor coverage are mitigated.

Nokia’s 5G transforms aviation inspections with ‘Virtual Table’

Nokia and Lufthansa Technik, a leading provider of aircraft services, have implemented a 5G industrial-grade private wireless network to enhance a project focused on remote engine parts inspection for civil aviation customers.

Through Lufthansa Technik's 'Virtual Table Inspection' at its Hamburg facility, the 5G network eliminates the need for physical customer presence, providing seamless video access to the engine overhaul shop floor. The 'Virtual Table Inspection' allows experts to assess engine repair decisions, replacing the previous requirement for customers to travel to Hamburg for in-person inspections.

The 5G network ensures a reliable stream as it seamlessly transitions across the hangar, offering stable, high-quality video streams for detailed inspections. This innovative use of 5G technology enhances efficiency, customer experience and collaboration between Nokia and Lufthansa Technik.

Nokia delivers 5G private wireless network in Japan

Nippon Steel is partnering with Nokia to enhance manufacturing efficiency through the installation of a private LTE network. This network facilitates 5G connectivity between various devices such as sensors, smartphones, and cameras, enabling remote monitoring and support.

The objective is to improve safety, minimize downtime and enhance maintenance productivity. The transition to 5G opens up possibilities for additional use cases, including autonomous factory vehicles and high-definition video monitoring. The collaboration highlights the potential of utilizing private spectrum for IoT adoption, showcasing how industries can leverage innovative solutions to advance workplace safety and overall operational efficiency.

Revolutionising British Sugar's manufacturing with Nokia's Private 4G Network

British Sugar, in collaboration with Virgin Media O2 Business and strategic partner Nokia, has implemented innovative private mobile network, spanning multiple factories in a significant 'Factories of the Future' transformation. Nokia's secure, low-latency Digital Automation Cloud (DAC) is at the core of the custom-built O2 4G network, linking British Sugar's facilities across three counties in the UK.

This advanced connectivity enables the integration of Industry 4.0 technologies, artificial intelligence (AI), robotics and drones, revolutionizing the sugar production process. The 4G private network, a result of a seven-year partnership with Virgin Media O2 Business, ensures uninterrupted connectivity for over 15 different digital manufacturing use cases.

Designed to be future-ready and easily upgradable to 5G, the initiative positions British Sugar at the forefront of Industry 4.0, enhancing efficiency, reducing downtime and fostering sustainable production practices.

Driving innovation at a smart factory in Finland

A world-leading producer of cutting-edge lifting solutions, Konecranes is committed to constantly innovating. With over 16,000 employees in 50 countries and 15,000 remote connections, Konecranes opened a smart factory at Hyvinkä to explore opportunities for technology innovation, development, evaluation, and deployment. Hyvinkä allows Konecranes to realize the enormous potential of wireless connectivity.

By doing so, it can continue to meet the digital transformation demands of its customers at ports, terminals, shipyards, and factories. To build the capabilities for Industry 4.0 and power automation, Hyvinkä leverages Nokia’s and Edzcom’s next-generation 5G standalone private network.

Nokia Digital Automation Cloud (DAC) 5G StandaloneSA private wireless network powers Konecranes’ technology evolution. With improved scalability, latency, and bandwidth, Konecranes offers its customers leading-edge connectivity solutions to create an ecosystem of connected machines, people, and devices. The result? Its customers’ operations are more efficient, more productive, safer, and future-proofed.

Accelerating digital transformation in Latin America

The alliance will bring Nokia’s industrial-grade private wireless network and digitalization platform solutions to enterprises across Latin America. It will be focused on four industries showing significant promise in Hispanic America: ports, mining, energy, and manufacturing.

The alliance will power South American industries into the future of Industry 4.0. Combining Nokia’s leading industrial-grade private wireless solutions with Teléfonica’s growing B2B solutions and services footprint across Latin America, the partnership will help businesses across the region to compete globally.

Companies can leverage LTE & 5G private wireless networks, which deliver a more pervasive broadband connectivity with lower latency, greater predictability, and higher security. Nokia is proud to embark on a game-changing alliance to boost digital transformation across Latin America.

Improving warehouse efficiencies with a Private LTE Network

Graybar, a Fortune 500 company, is a leading North American distributor of electrical, communications, data networking and industrial products. With over 325 locations, a streamlined warehouse operation is key to success, but challenges around connectivity meant it was falling short of where it wanted to be.

Graybar teamed up with Nokia to power its warehouse digital transformation, utilizing Nokia Digital Automation Cloud (DAC) private wireless solution. The aim: next-generation connectivity that would get products and materials out of its warehouses as efficiently, safely, and cost-effectively as possible, improving customer service and enhancing operations for its warehouse workers.

Previously, Graybar experienced regular connectivity interruptions, which resulted in the warehouse grinding to a halt. It also suffered from connectivity dead spots, which would change location daily. By introducing DAC, all dead spots were eliminated, and Graybar enjoys consistent wireless connectivity throughout the warehouse. The result? Faster speeds, more robust security features, and a seamless operator experience – all while saving costs.

Empowering YOFC’s digital transformation to a smart factory

A global manufacturer of optical cables, YOFC required a business-critical digital transformation of its Hanchuan campus in east-central China. Its goal was to drive production efficiency and business competitiveness, and it wanted to do so by deploying a private network at the heart of the campus.

YOFC partnered with Nokia Shanghai Bell, and used Nokia Digital Automation Cloud to develop a smart factory solution. By establishing its reliable and efficient low-latency wireless network, Nokia transformed the Hanchuan campus into a state-of-the-art environment that can accommodate emerging smart factory applications, systems, and processes. Simply, Nokia has future-proofed YOFC’s campus.

The transformation has enabled seamless connection throughout the site, powering the intelligent management of smart devices and production equipment. The result? Improved production efficiency and quality, increased security, and reliable stability across all of YOSF’s operations.

An industry first in chemicals

A global leader in the chemical industry, BASF operates the largest chemical factory in southern Europe. To improve safety, drive production efficiency and ensure future-proofing for Industry 4.0, BASF implemented the first 5G private network in Spain and the first in the chemical industry.

Nokia sees strategic partnerships as key to providing real value for customers. So, to deploy the 5G network at BASF, Nokia collaborated with Spanish wireless telecommunications infrastructure and services company Cellnex.

The mission-critical results were immediate. The low network latency enables automated vehicles to be operated safely across the entire site. It has also improved worker safety by installing tracking devices on workers’ helmets with a safety button that pinpoints their precise location. The high-performing network means workers can access augmented reality on devices that scan issues such as broken pipes, and immediately access real-time information to fix the problem.

Upgrading plant connectivity across 20 square miles

In the vast landscape of Dow's Freeport site, the largest integrated chemical manufacturing complex in the Western Hemisphere, a digital program is reshaping plant maintenance. Dow has integrated technology to enhance safety, agility, and reliability across its 40 production plants spanning 20 square miles.

At the heart of this transformation is Dow's adoption of a private LTE network, a cornerstone in its digitalization strategy. It worked in collaboration with Kyndryl to establish the requirements for the entire complex. This technological leap empowers on-the-ground technicians with real-time connectivity through tablets and smartphones, replacing cumbersome paper-based methods. Streamlined communication facilitates efficient decision-making, particularly in a complex and expansive industrial setting.

Nokia and Kyndryl expanded their global network and edge computing partnership. The three-year agreement includes plans to co-innovate and accelerate the deployment of flexible, reliable, and secure LTE and 5G private wireless connectivity services and Industry 4.0 solutions.

Simplifying processes in the chemical industry

The manufacturer is looking to the future at its chemical plant in Ottmarsheim, France. There, it creates technical plastics, industrial fibers, and elevated coatings across automotive, textile and consumer goods industries. Butachiminie wanted to simplify processes, improve security, embrace sustainability and future-proof its production chain to maintain an advantage in a competitive marketplace.

To achieve this, Butachiminie turned to Industry 4.0. It chose Nokia and Orange to modernize its facilities with a private LTE network, and the partnership is turning the plant into a Factory of the Future.

The low-latency 4G LTE network has delivered a catalog of future-proofed benefits. Connected video surveillance monitors plant access and the chemical production processes, while push-to-talk and push-to-video connectivity facilitate reliable communication between on-site workers and remote experts. On top of that, IoT sensors enable real-time condition monitoring and management of critical assets, as well as asset and worker localization.

Industry-leading network slicing in Germany

The Port of Hamburg is Germany’s largest port, and sits on the river Elbe, 110km from the North Sea. The third-largest container port in Europe, it handles millions of containers every year, and thousands of trucks a day, employs almost 2,000 people, and is home to around 100,000 mobile sensors.

This volume of industry, mixed with a vast collection of roads, bridges, waterways, and railways, needs innovative connectivity solutions to deliver operational efficiency. The Hamburg Port Authority, Nokia, and Deutsche Telekom collaborated on a field trial to deploy a 5G network with next-generation slicing functionality. This pioneering approach saw one network slice created for three use cases: ultra-reliable and low-latency communications; enhanced mobile broadband; massive machine-type communication.

Implementing a digital transformation project in a complex industrial environment is challenging. However, the field trial significantly improved productivity at the Port of Hamburg and delivered environmental and social benefits.

A next-generation port in Finland

The Port of Oulu covers three harbors in Oulu, on the north-west coast of Finland. It is a complex environment, with an average of 3m tons of cargo shipped yearly and facilities for oil, chemicals, and container freight. The digital transformation of such a challenging industrial operation requires specialist knowledge, and that’s where Nokia and Ukkoverkot come in.

The partnership between Nokia and Ukkoverkot Edzcom spearheads the Port Oulu Smarter digitalization project. Introducing a private wireless network brings reliable mobile broadband connectivity to the port. Through sensors and cameras, it connects machines and people across the port, with cranes, lifts, and vehicles all receiving and transmitting data to a single, easily-accessible platform.

The digital transformation has improved efficiencies across the port, benefiting customers, partners, enterprises, and local businesses.

Ruggedized industrial devices for ports

Part of the Cargotec Corporation, Kalmar delivers innovative and eco-efficient cargo-handling equipment, automated terminal solutions, software, and support services for ports worldwide.

It operates a groundbreaking testing center in Finland, with the goal of advancing port automation technologies. This wouldn’t be possible without collaboration. So Kalmar has partnered with Telia, Digita, and Nokia to optimize communications and connectivity. Using Nokia's Digital Automation Cloud (DAC), they implement end-to-end industrial-grade private 4G and 5G wireless networks to power greater port automation by offering low latency and pervasive connectivity.

Integrated with Nokia’s ruggedized industrial user equipment that operates in harsh and remote environments such as ports, the technology connects people and machines across complex industrial environments. As well as improving operational and production efficiency, advanced automation reduces wastage, carbon emissions, and slow-downs at ports.

Optimizing marine freight operations

One of the largest container ports in the US, the Port of Tacoma is spread across 2,500 acres and is home to five major container terminals. One of those terminals, Husky Terminal and Stevedoring, turned to Nokia to optimize freight operations. Nokia deployed the private 4.9G/LTE network to support the terminal’s digital upgrade.

The next-generation technology removes the performance and productivity issues for mission-critical applications traditionally encountered with Wi-Fi. It moves the port to a cloud-based terminal operating system (TOS) that can be accessed remotely from anywhere.The network leverages Nokia industry-grade Digital Automation Cloud (DAC), increasing capacity supported by secure low latency connectivity across Husky Terminal’s 115-acre container yard.

The transformation means the regular downtimes and disconnections previously experienced over Wi-Fi are a thing of the past. In its place are future-proofed digital services that have reduced costs, streamlined operations, and surpassed customer expectations.

An industry-first in Colombian port terminal

Nokia and Claro have partnered to deliver the first industrial-grade private 4.9G wireless network in a maritime terminal in Colombia. The Sociedad Portuaria Puerto Bahía, on Colombia’s Caribbean coast, is blazing a trail as the first multipurpose terminal to adopt a private 4G technology in Latin America.

Puerto Bahía is the largest private hydrocarbon terminal in Colombia. It also handles general cargo and provides logistics and offshore exploration services. Connecting such an asset-heavy industrial site is challenging. Still, the private network - powered by Claro and using the Nokia Digital Automation Cloud (DAC) platform - connects hundreds of workers, sensors, vehicles, and equipment. This includes tracking up to 20,000 vehicles and connecting cranes in docks and yards.

Puerto Bahía is optimizing operations and saving costs by improving network predictability across the whole site. The technology is built to be adaptable, allowing new use cases to be added throughout the digital transformation roadmap.

Cleaning up the oceans with wireless connectivity

The international non-profit organization has partnered with Nokia to develop and scale technologies that tackle the enormous environmental impact of plastic in our oceans. In the last decade, more plastic has been produced than in the previous century, making up 80 percent% of all marine pollution.

Nokia deploys private wireless connectivity, network edge equipment, and analytics to Ocean Cleanup. Nokia’s high-performance, end-to-end private wireless networking and edge computing platform, Digital Automation Cloud (DAC), and Nokia MX Industrial Edge (MXIE) will help navigate operations such as plastic harvesting in the Great Pacific Garbage Patch.

From subsea optical fiber networks to acoustic sending technology, Nokia is committed to using its technology to relieve pressure on the environment and natural ecosystems.

First-ever 5G port network in Latin America

The partnership will deliver South America’s first-ever 5G private wireless port network, at Santos Port Brasil Terminal Portuário (BTP). Brazil’s largest port, BTP connects with over 600 ports in 125 countries and handles over 100 million tons of cargo each year.

The private 5G network will drive the digital transformation of BTP’s container terminal operations in Santos. Deployed by Brazilian mobile carrier TIM, and based on Nokia’s leading-edge network equipment and solutions, the pioneering technology will improve operational efficiency, significantly boost equipment connectivity, and streamline communications among the 1,400 terminal employees.

Enabling real-time monitoring of equipment - remotely, from anywhere - improves the productivity and safety of operational activities, including using cranes. Nokia is proud to work with BTP to stay at the cutting edge of port and terminal operations across Latin America.

Digitalizing HaminaKotka port with private LTE

Port operator Steveco has embraced a high-capacity mobile broadband network to power a digital transformation at the Port of HaminaKotka in Finland. Nokia and Edzcom have collaborated to provide a private LTE network to the port, with the dedicated low-latency network driving efficiencies across operations.

The network enables connectivity for sensors, vehicles, robots, and workers. Remote mobile access to mission-critical applications and information has improved situational awareness of port logistics and container handling and enhanced security. Meanwhile, connected cameras provide reliable real-time video streaming, advanced data analytics, and asset tracking.

The digital transformation isn’t only for now. It is also for the future, with Nokia’s technology solutions helping Steveco to embrace the Internet of Things, automation, AI, and machine learning to boost productivity and reduce costs.

Breaking new ground in port operations in San Antonio

The San Antonio Terminal Internacional (STI) was transported to the future with the addition of Nokia’s private network. The private wireless network uses 4.9G LTE to deliver low latency and reliable connectivity across the entire site, with the technology based on the Nokia Digital Automation Cloud (DAC) platform.

STI is Chile’s main port terminal and is of significant importance in South America. To maintain its competitiveness in a challenging marketplace, STI’s business-critical objective is to optimize its operation and service through a digital transformation. Nokia’s state-of-the-art network powers this transformation, enabling remote and autonomous operations and faster, more reliable, and secure data transmission.

Connecting workers, vehicles, and machines in a Mexican port

The industrial-grade LTE private network is the first to be used in a maritime terminal in Mexico. The state-of-the-art technology is deployed at the APM Terminals terminal in Puerto Progreso in Yucatán. Using 4.9G LTE, it delivers pervasive high-bandwidth, low- latency connectivity across the terminal’s 11.5 hectares.

The private network is a significant step in the terminal’s digital transformation journey. It connects hundreds of workers, sensors, vehicles, and equipment across the terminal. With security and reliability at its heart, the network allows APM Terminals to expand its digitalization and automation strategy.

The network is based on Nokia’s (DAC) platform, a high- performance,end-to-end private wireless network and edge computing platform. Built for the future, DAC enables APM Terminals to introduce new capabilities, such as remote and autonomous crane operations at the terminal.

Transforming the UK’s first 5G port

Every year, the Port of Southampton, on the UK’s south coast, handles over £450bn of UK exports, transports nearly 600,000 vehicles, and welcomes over 1m cruise passengers. Simply, it is critical to the global economy. But, like any big business, it needed to evolve digitally to remain competitive.

Associated British Ports, which runs the Port of Southampton, brought in Nokia and Verizon to create a state-of-the-art smart port. Nokia’s and Verizon’s 5G platform provides a low-latency and secure private network connection. The network drives efficiencies, flexibility, and security while keeping the many thousands of people who work at the port connected through ultra-fast communications across all terminals.

From automated drone flights to utilizing computer vision, and from developing simulations of port operations with machine learning to providing real-time product information, the Port of Southampton is truly a global leader in innovation.

Driving innovation at a smart factory in Finland

A world-leading producer of cutting-edge lifting solutions, Konecranes is committed to constantly innovating. With over 16,000 employees in 50 countries and 15,000 remote connections, Konecranes opened a smart factory at Hyvinkä to explore opportunities for technology innovation, development, evaluation, and deployment. Hyvinkä allows Konecranes to realize the enormous potential of wireless connectivity.

ABy doing so, it can continue to meet the digital transformation demands of its customers at ports, terminals, shipyards, and factories. To build the capabilities for Industry 4.0 and power automation, Hyvinkä leverages Nokia’s and Edzcom’s next-generation 5G standalone private network.