- Industry 4.0. self-assessment tool

- At a glance: The connected digital mine

- Private wireless networks for open-pit and underground mines

- Mining Transportation Digitalization

- High-performance wireless connectivity

- Connected mine spotlight: Boliden Kevitsa

- Nokia solutions for mining digitalization

- Book a demo

- When the going gets tough

- Learn more about mining

- Resources

Transforming mining operations with Industry 4.0 technologies

Make people, technology and processes work as one

Why do mines need to go digital?

Digitalization promises to make mining operations safer, smarter, more efficient and more sustainable. But mining companies face significant challenges on the road to digitalization. Digital systems and technologies will need to be integrated across mining operations and sites, a complex task that demands careful planning and coordination. Companies will also have to spend time and other resources on talent acquisition or upskilling to be able to adopt and manage those technologies — and to keep the sensitive data they contain safe from cyber threats.

What mining companies need is a strategic and collaborative approach to digitalization, along with a next-generation network capable of supporting mission-critical operations.

Industry 4.0. self-assessment tool

Is your mining site ready for Industry 4.0? Find out with our Industry 4.0 maturity and readiness self-assessment tool and benchmark your progress against other mining companies. You will get the results instantly.

At a glance: The connected digital mine

Digital technologies and use cases can transform mining operations, enabling a broad range of applications such as:

- Autonomous vehicles

- Geolocation, tracking and fencing

- Augmented reality

- Enterprise LAN/WAN, data center and cyber security

- Predictive asset maintenance

- Mission-critical voice and video communication

A high-performance, mission-critical network is essential to reliably connect digital technologies across a mining company’s operations — and to realize the many compelling benefits of Industry 4.0, ranging from safer conditions for workers to greater efficiency across sites.

Private wireless networks for open-pit and underground mines

The digitalization of the mining sector requires robust, pervasive and predictable wireless voice and data connectivity to enhance critical communications and enable the next generation of smart digital applications.

Whatever type of mine you operate; Nokia has the knowledge and experience to help you embrace Industry 4.0 with high-performance private wireless connectivity, a mission critical industrial edge with a wide range of applications and ruggedized 4G and 5G devices and handhelds.

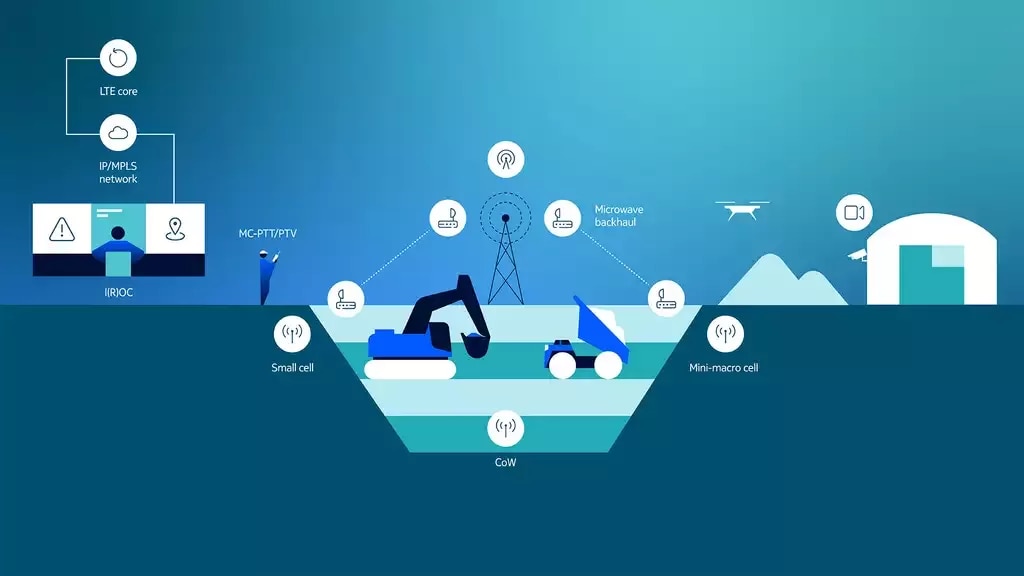

Connecting open-pit mines with private wireless

Our private wireless network solutions can provide critical connectivity to power new use cases and technologies across open-pit sites, supporting everything from autonomous hauling and remote-control drilling in the pit to inspection drones overhead.

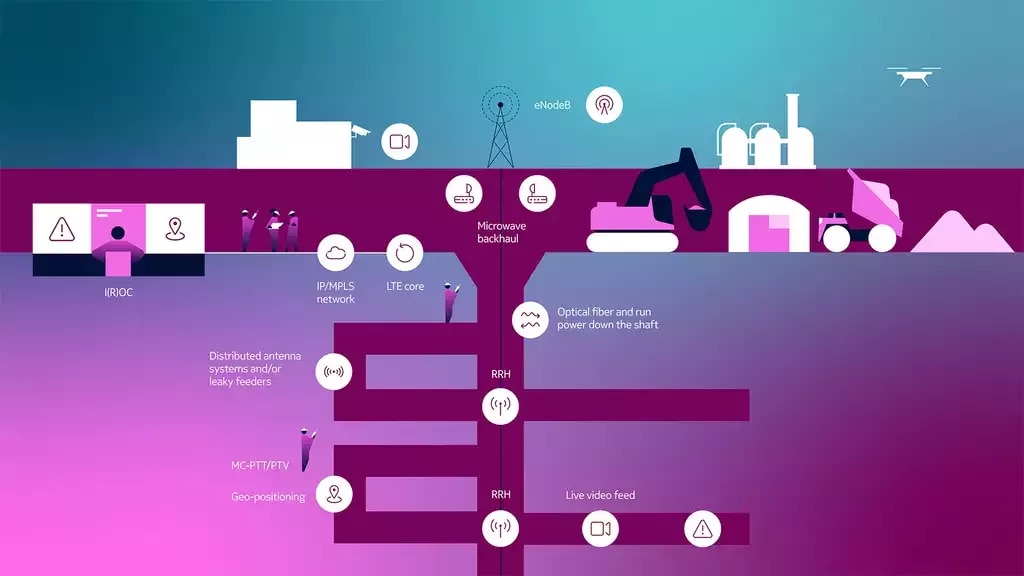

Bringing private wireless to underground mines

Our private wireless network solutions can provide critical connectivity to power new use cases and technologies across open-pit sites, supporting everything from autonomous hauling and remote-control drilling in the pit to inspection drones overhead.

Thoughtful network planning, design and deployment are essential to bringing reliable wireless connectivity to underground operations. Find out why Nokia leads the way in 5G underground mining deployments.

Industry-first private wireless TCO calculator

Compare the costs of the wireless connectivity options available to your mining operation.

Powering the connected mine with high-performance wireless connectivity

Many mining sites are held back by aging communications infrastructures that lack the capacity, reliability, security and mobility required to support automated mining operations. To take advantage of digital technologies and applications, mining companies need networks that deliver:

Fast and reliable mobile data connectivity

High capacity to support sensor networks, IoT devices, AI and analytics

Low latency for extreme autonomy and automation

Built-in security to ensure safe, reliable connectivity

Mission-critical voice and video communications

Deep, wide coverage to connect everyone and everything

Connected mine spotlight: Boliden Kevitsa

Mining companies are working hard to meet stringent environmental regulations while keeping their employees safe in remote and harsh environments.

Finland’s Boliden Kevitsa uses private wireless connectivity deployed by Nokia to enable automation in the pit, even in extreme temperatures of -26° Celsius.

Nokia solutions for mining digitalization

The leading private wireless supplier for mining, we are shaping the industry’s digital transformation with the Nokia One Platform for Industry Digitalization. It includes industrial-grade private wireless connectivity and Wi-Fi, industrial devices, mission-critical industrial edge, and an application ecosystem that meets and addresses the industry’s business needs for Industry 4.0. Together, these solutions enable all of a mine’s workers, vehicles and machines to work together safely, efficiently and sustainably.

Connectivity solutions

New applications demand robust wireless connectivity beyond what Wi-Fi can provide, requiring solutions that can cover both indoor and outdoor areas.

Nokia Digital Automation Cloud (DAC) complements private wireless with Wi-Fi 6/6E for flexible mission-critical connectivity.

Mission-critical industrial edge (MXIE)

Industrial applications

Integrated industrial devices

New applications demand robust wireless connectivity beyond what Wi-Fi can provide, requiring solutions that can cover both indoor and outdoor areas.

Nokia Digital Automation Cloud (DAC) complements private wireless with Wi-Fi 6/6E for flexible mission-critical connectivity.

Nokia MXIE is an on-premises solution for digital transformation, processing data locally for greater security and supporting high-bandwidth applications like video surveillance.

Its ecosystem-neutral application catalog simplifies deployment.

Our ecosystem-neutral industrial applications catalog includes Nokia and third-party applications to provide you with proven options to meet your digitalization needs.

Our applications run on MXIE and can be deployed instantly.

Our industrial devices enhance connectivity in mining digitalization with 4G and 5G handhelds (IP67-rated, some ATEX/IECEx certified), enhancing worker safety and efficiency.

Book a demo

Contact us now to find out how our solutions could maximize the true potential of your operations.

Asia Pacific and Middle-East Europe Latin America North America

Our customers say

Learn more about mining

Resources

Ready to talk?

Please complete the form below.

The form is loading, please wait...