Real-time tracking and positioning

Your route to seamless, flexible and on-time operations

Boost asset visibility and situational awareness with real-time tracking and positioning

Anyone operating in an industrial environment knows what a significant problem poor asset visibility can be. Whether you’re running a manufacturing plant, a port terminal, a mining operation or any other industrial site, lost, misplaced and stolen assets can seriously impact your performance and profits. Inefficient work processes and the sub-optimal use of machines and equipment are often silent drains on productivity too, with idle and underused machines and vehicles slowing return on investment to a standstill. Poor visibility into processes and workflows is also a common cause of workplace accidents.

The real-time tracking and positioning of assets is a crucial part of the solution as well as the cornerstone of Industry 4.0 digitalization. One reason why many enterprises invest in tracking and positioning solutions early in their digital transformation journey is their wide application range and the ability to meet many different business needs.

Where are your inefficiencies? Download our guides to boost your operational visibility

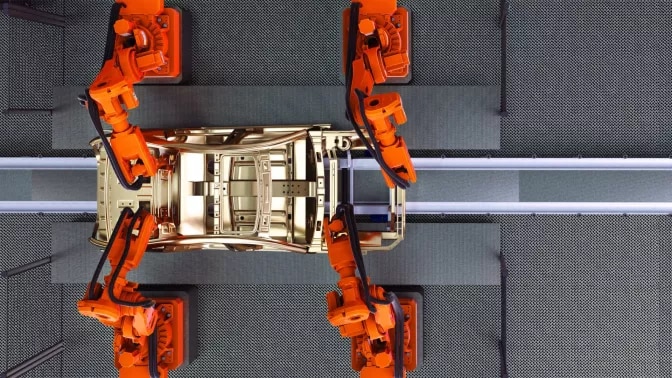

Manufacturing

Searching for missing tools, spare parts, raw materials and finished goods is a daily headache in large manufacturing plants with hundreds of workers, tight production schedules and increasingly flexible layouts in which AGVs/AMRs roam the site. Download our guides below to explore the use cases and advantages of real-time tracking and positioning, key technologies for successful implementation, and how Nokia one platform for industrial digitalization offers simplified deployment with lower TCO and faster time to market.

Port terminals

Searching for missing tools, spare parts, raw materials and finished goods is a daily headache in large manufacturing plants with hundreds of workers, tight production schedules and increasingly flexible layouts in which AGVs/AMRs roam the site. Download our guides below to explore the use cases and advantages of real-time tracking and positioning, key technologies for successful implementation, and how Nokia one platform for industrial digitalization offers simplified deployment with lower TCO and faster time to market.

Around 90% of the world’s cargo is moved as sea freight, making port terminals highly congested, complex environments. Staff are under pressure to move containers to the right spot at the right time as efficiently as possible, across vast sites often spanning hundreds of square kilometers. Download our guides below to explore the use cases and advantages of real-time tracking and positioning, key technologies for successful implementation, and how Nokia one platform for industrial digitalization offers simplified deployment with lower TCO and faster time to market.

What is real-time tracking and positioning for industrial sites?

Real-time tracking and positioning is the ability to locate and track the position of your physical assets in the moment, anywhere, both indoors and outdoors, right across your extended industrial site. These assets might be anything from raw materials to finished goods, machines or workers and are likely to be crucial for successful operations. By gaining greater asset visibility you can significantly boost operational performance.

Transform location data into AI-powered contextual awareness

Enhance operational visibility with advanced location information across your industrial site with MX Context: Tracking and Positioning. Using sensor fusion technology, this solution suite enhances contextual awareness by integrating diverse data from various tracking and positioning technologies, ensuring accurate and reliable positioning, and maintaining tracking continuity across different environments. Advanced AI algorithms process the harmonized sensor data to deliver real-time insights and predictive recommendations, enabling informed decision-making and advanced automation. This drives operational excellence in critical areas such as asset utilization, inventory management, process efficiency and worker safety.

What business challenges does real-time tracking and positioning solve?

A lack of asset visibility is the root cause of many challenges in industrial environments - especially in complex manufacturing, port terminal and mining operations. Real-time location systems (RTLS) can help solve these challenges and many more to significantly improve productivity, operational efficiency, cost savings and worker safety.

20%

of operators’ time is spent searching for tools ¹

€630 billion

is the cost of inefficient resource utilization for European industry every year ²

USD $142,000

is the value of surplus stock an average manufacturer holds each year ³

Sources: 1) Sandvik Coromant, 2) Greenovate Europe, 3) Unleashed Software

Lost or stolen assets and raw materials

A great deal of valuable time, money and human resource is wasted every day locating missing assets. This can even result in operations grinding to a halt which incurs significant costs for companies in unplanned downtime and can lead to a negative customer service. If materials or goods go permanently missing, it’s expensive and constitutes unnecessary waste which impacts sustainability goals.

Inefficient asset utilization and work processes

When machines and systems aren’t used at optimum or site layouts and workflows hinder efficiency, industrial enterprises deliver a poor return on asset investments and productivity and profitability take a hit.

Poor inventory management

If you can’t see what you really have, it’s easy to misjudge storage capacity and restock requirements. The overstock or understock of assets, materials and equipment parts can cause unnecessary cost and production inefficiencies and can lead to unplanned downtime.

Dangerous workplace situations

A lack of visibility into the whereabouts of moving assets, workers and historically accident-prone areas is the root cause of many industrial accidents and can lead to non-compliance with safety protocols.

What are typical tracking and positioning use cases?

Industrial tracking and positioning solutions address a variety of use cases and enhance the visibility over equipment, machines and people to meet the unique needs of businesses in a whole range of sectors. Are you looking to track mobile assets like AGVs/AMRs, forklifts and straddle carriers, keep tabs on valuable boxes of inventory or bring visibility to zones that are accident hotspots? Whatever your industry sector or operational requirement, there’s a tracking and positioning solution for you.

A wide variety of technologies and solutions are available to solve different challenges from indoor and outdoor tracking to gaining visibility over mobile assets and keeping workers safe. Deploying the right real-time location system (RTLS) will rapidly become a key contributor to your overall business performance, whether you’re working in manufacturing, a port terminal, mining or any other industrial operation.

How to use real-time tracking and positioning to improve productivity, efficiency and safety.

The diagram below shows how indoor location tracking and outdoor location tracking solutions can solve a series of industry challenges and help enterprises to improve their operational performance.

What are the business benefits of real-time tracking and positioning?

Real-time tracking and positioning gives you crucial end-to-end asset visibility across your operations and sites and drives measurable business benefits for more seamless, flexible and on-time operations.

Amplify visibility

Bring crucial visibility to every part of your operation by tracking and positioning any asset, anywhere on your site. Uncover hidden inefficiencies and danger blackspots and move to solve them fast.

Inform decision-making

Know when and where to optimize processes and workflows with real-time and historical data. Identify bottlenecks and inefficiencies in your day-to-day operations to improve performance.

Operate smarter

Accelerate return on your asset investments, improve workflows and always have the right-sized stock at hand. Boost the productivity, efficiency and safety of your operations while supporting cost savings and more sustainable work processes.

Which tracking and positioning solutions can help me realize benefits fast?

At Nokia, we can help you make the right deployment decision based on what’s best for your business. Depending on the nature and layout of your industrial site, some solutions will address your needs better than others.

We offer a comprehensive tracking and positioning suite that brings different asset tracking scenarios to life, across both your indoor and outdoor operations. Our expert teams can advise you on which solution and deployment model is best for your specific sector, use case and business need.

Our tracking and positioning suite is also natively integrated with the Nokia one digital platform, bringing reliable wireless connectivity, on-prem edge computing and industrial devices to your operation alongside our tracking and positioning applications – for speedy and straight-forward deployments.

Book an expert consultation

Speak to one of our experts to discuss how real-time asset visibility can transform your operation for improved productivity, efficiency and safety.

Asia Pacific and Middle-East Europe Latin America North America

Real-time tracking and positioning on the Nokia one digital platform

Explore the technologies that power real-time tracking and positioning

Real-time tracking and positioning needs the right technology foundation to ensure secure, reliable and always-on performance in complex industrial environments. The Nokia One Digital Platform is designed to be at the heart of every tracking and positioning and Industry 4.0 use case you implement.

It makes industrial digitalization simple – and business impact palpable – providing reliable wireless connectivity, on-prem industrial edge computing, ruggedized devices and a whole catalogue of ecosystem-neutral applications to choose from.

The illustration below shows how the Nokia one digital platform enables real-time tracking and positioning and wider Industry 4.0 digitalization. Tracking and positioning and other Industry 4.0 applications are deployed directly from our application catalog and enterprises can choose from a continuously growing portfolio from Nokia and a wide ecosystem of best-in-class partners. Our easy-to-deploy private wireless solution gives you a robust connectivity foundation and ensures your assets stay connected, no matter what. All your applications as well as your private wireless network are powered by Nokia MX Industrial Edge (MXIE) which provides secure and robust edge computing capabilities for mission-critical availability and low-latency performance. MXIE resides directly on your premises, meaning sensitive and mission-critical OT data stays local for increased data security and sovereignty.

How does real-time location tracking help make the smart factory a reality?

Real-time location tracking has helped Chennai Factory become an Industry 4.0 smart factory. By digitalizing their assets, Chennai Factory was able to optimize sorting and storage locations, enhance their site layout to reduce non-productive walking, and transform asset utilization rates, among other things. Read the case study to learn more.

Learn more

Make real-time tracking and positioning a reality.

Empower your business to accelerate Industry 4.0 digitalization.

Please complete the form below.

The form is loading, please wait...