Pit-to-port transportation

Digitalization of pit-to-port transportation unlocks

new levels of efficiency and operational excellence.

In the age of digitalization, pit-to-port transportation in the mining industry is undergoing a revolution. Traditional approaches are being replaced by innovative digital solutions that optimize logistics, boost efficiency, and increase productivity.

Digitalization enables the real-time tracking and monitoring of mining transport operations, providing valuable insights and data-driven decisions. Advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and automation are being used to streamline processes, reduce downtime, and optimize resource allocation.

Mining companies can achieve greater operational efficiency, minimize costs, and improve safety through digitalization. Real-time data integration and analysis enable predictive maintenance, ensuring timely repairs reduce equipment downtime.

Additionally, digitalization enables seamless coordination and communication across the entire pit-to-port transportation ecosystem, from mine sites to ports and processing plants. This results in improved supply chain management, reduced costs, fewer delays, and greater customer satisfaction.

The transformative impact of digitalizing mining transportation is not limited to operational efficiencies but also unlocks opportunities for sustainable practices through better resource management, lower emissions, and optimized energy consumption.

By adopting digitalization, mining transport players can revolutionize their operations, remain competitive in their industry, and pave the way for a more efficient and sustainable future.

What is mining transportation digitalization?

Mining transportation refers to the holistic process of transporting mined materials from the pit to a designated port for further processing, refining, distribution, or export. Logistics and infrastructure must be integrated and optimized to ensure materials are transported safely and efficiently.

A pit-to-port solution embraces various transportation methods, including trucks, trains, ships, and conveyor systems, depending on the distance, terrain, and available infrastructure. Transportation may involve loading mined materials onto vehicles or conveyor belts, transferring them between vehicles, and unloading them at the destination, such as a processing plant, warehouse, or port.

Efficient pit-to-port transportation is critical to mining operations' overall productivity and profitability. It requires careful coordination, route optimization, adherence to safety protocols, and effective logistics management to ensure on-time delivery while minimizing costs and environmental impact.

20%

Digitalization can reduce logistics costs.

McKinsey & Company Study

The most typical use cases for pit-to-port digitalization

Mining pit-to-port services incorporate a comprehensive set of activities associated with transporting mined material from the extraction site (the pit) to the final export destination (the port or other destination). These services are critical to ensure the efficient and timely transportation of minerals, ores, or other resources from the mine to global markets.

The diagram above shows the most frequent use cases and how digitalizing pit-to-port can solve these challenges to improve operational performance.

up to 30%

Digitalization can reduce the environmental impact of mining transportation.

United Nations Environment Program (UNEP)

Enabling digital transformation use cases from pit-to-port

Regarding pit-to-port transportation, digitalization starts with identifying use cases that specifically address the operator’s most significant challenges or problems. Mining transportation encompasses a wide range of use cases that involve the movement of minerals, ores, and other materials from mining sites to processing plants, ports, or other destinations. These use cases vary depending on factors such as the type of mining operation, distance to the destination, infrastructure availability, and logistical requirements.

Economic and financial benefits of

pit-to-port digitalization

Transportation from the pit to the port is essential to a profitable mining operation and represents a significant cost factor. Mining companies have recognized the strategic importance of transportation and are deploying innovative digital solutions that drive significant economic and financial results.

In this eBook, you will learn how a Nokia partner company has achieved economic and financial results by digitizing mine-to-port transportation

What are the business benefits of digitalizing

pit-to-port transportation?

The digitalization of pit-to-port transportation has the potential to unlock several business benefits. Depending on the extent of digitalization, the level of technology adoption, and the unique characteristics of each mining transport operation. However, digitalization can improve efficiency, safety, decision-making, and sustainability, resulting in competitive advantages and better business outcomes in the mining transportation sector.

Transportation cost reduction

Digitalization reduces costs in several ways, such as improved logistics planning and route optimization, which can reduce fuel consumption and transport costs. Predictive maintenance also reduces costs, leveraging real-time system data to ensure maintenance activities are implemented before downtime can occur.

Improved logistics planning

Digitalization provides better visibility and control over the supply chain and enables more accurate logistics planning. Real-time data on stock levels, transport routes, and equipment performance allow companies to optimize scheduling and coordinate routes, resulting in reduced lead times and better customer service.

Increased operational efficiency

Digitalization enables capabilities such as real-time monitoring, data analysis, and automation, improving the efficiency of pit-to-port transportation through optimized routes and asset utilization. These can, in turn, reduce costs, increase productivity, and improve performance.

Enhanced safety

Implementing digital technologies to collect data from IoT sensors during the pit-to-port journey opens the door to predictive analytics and real-time monitoring, which can help identify potential risks and enable timely intervention. Reducing the potential for accidents and improving the safety of personnel, equipment, and cargo.

Scalability and flexibility

Digital technologies and platforms are up or down depending on business needs. This adaptability enables companies to respond quickly to changes in demand, market conditions, or operational requirements. It also supports the integration of new technologies and the ability to adapt to future advances in the industry.

Sustainability and environmental impact

Digitalization can reduce fuel consumption and emissions during pit-to-port transportation by optimizing routes and logistics efficiency. Digital technologies also increase environmental performance by tracking environmental effects and compliance.

30%

Digitalization can improve the efficiency of pit-to-port transportation operations.

International Council on Mining and Metals (ICMM) Study

50%

Digitalization can halve the number of accidents in the mining transportation.

National Institute for Occupational Safety and Health (NIOSH) Study

$100 billion

The value of digitalization could save for the global mining industry.

World Economic Forum Report

$100 - $200 billion

The value of digitalization could boost global mining productivity.

Boston Consulting Group Report

Overall, the benefits of pit-to-port transportation digitalization are significant and far-reaching. Using digital technologies, companies in the mining transportation sector can improve efficiency, productivity, safety, and profitability and reduce costs and their environmental impact while creating new growth opportunities.

Technical solution for pit-to-port digitalization

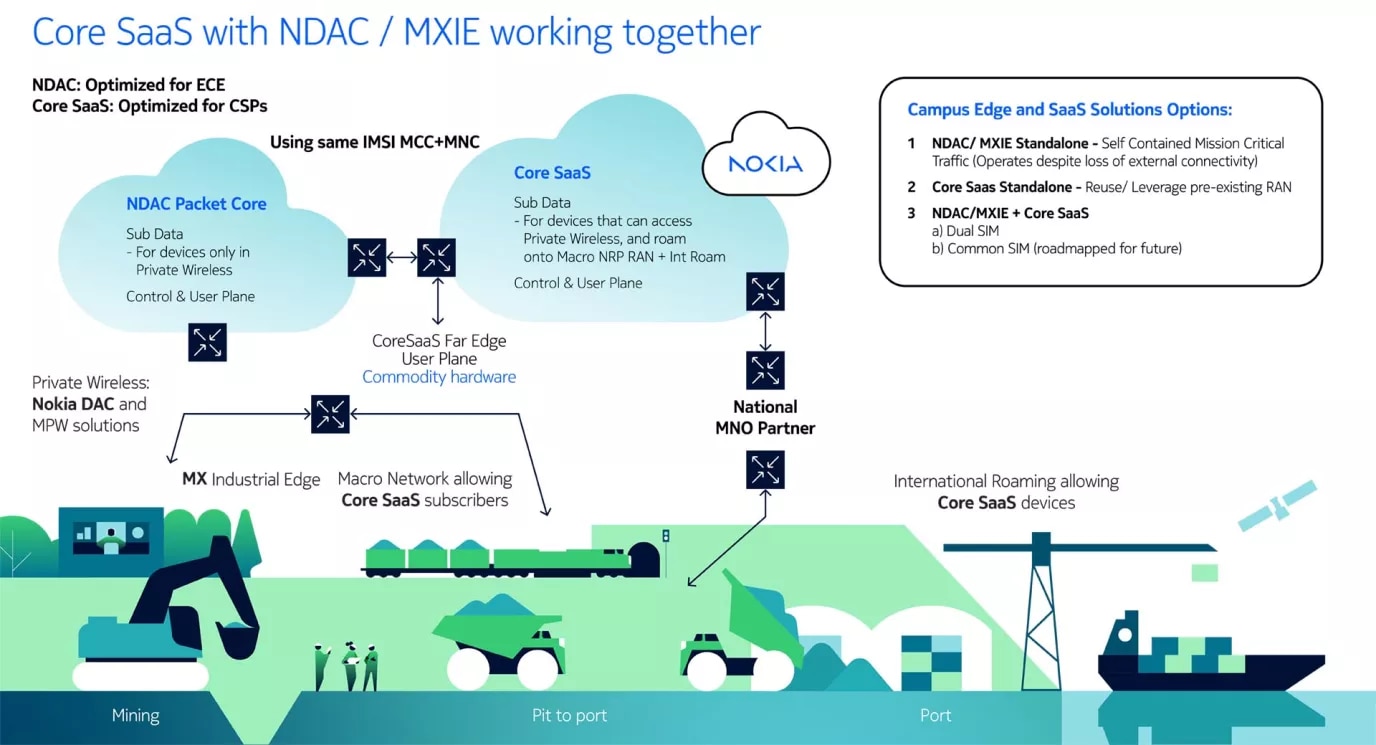

This illustration demonstrates the transformative approach of digitalization in mining transportation and shows a sophisticated network of interconnected systems. This captivating visualization reveals a comprehensive technical solution that synthesizes cutting-edge technologies to provide the ability to plan, manage, and monitor mining transportation with unprecedented precision.

Simplifying Industry 4.0 digitalization requirements

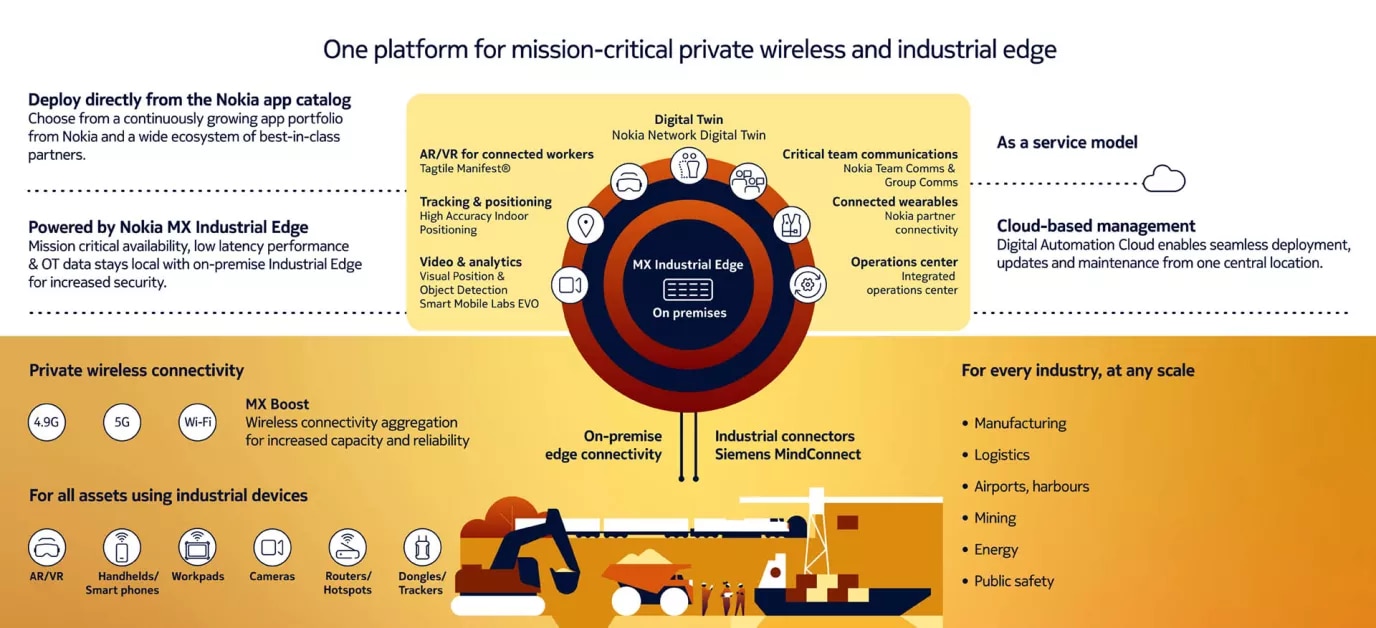

Nokia simplifies digital transformation with one digital platform that provides multi-technology connectivity, Industrial Edge, applications, and devices.

Make your mining site work as one

Nokia helps mine operators accelerate their Industry 4.0 transformation with one digital platform that includes mission-critical Private Wireless, Wi-Fi, Industrial Edge, devices, and applications. This unified platform enables all mine employees, vehicles, and machines to work together securely, efficiently, and sustainably.

Contact with Nokia mining advisor

Please complete the form below.

The form is loading, please wait...